A Review of Flexible Battery Manufacturers

Flexible batteries, though not commonly known, are used in a variety of products, particularly wearable devices, such as smart bands that monitor users’ health. Per their name, flexible batteries must be able to withstand constant twisting, rolling, and bending to suit their products’ needs.

In this article, we will explore the different types of flexible batteries, as well as the different manufacturers of such batteries.

Lithium-ion Polymer Flexible Batteries

There are three main issues that must be taken into consideration with flexible batteries:

First, after repeatedly twisting a flexible battery, cracks in the electrode sheet can appear and cause the active material to fall apart. In other words, there is limited adhesion strength between the electrode material and current collector.

Secondly, the gap between the anode and cathode continuously changes with the degree of constant twisting, which causes the internal resistance of the battery to increase. Therefore, flexible batteries must have better stability between the anode-separator-cathode layers.

Finally, there is the problem of the battery pack itself. The aluminum plastic film is generally not an issue for typical lithium batteries; however, it is easy to wrinkle, so it causes problems as a flexible battery if the electrode layers are pierced and start to leak in any way.

CATL

Unlike flexible OLED screens that are everywhere, there are only a handful of manufacturers claiming to be able to develop flexible Lithium-ion Polymer batteries. The domestic consumer lithium-ion battery giant CATL has previously demonstrated a flexible battery using a polymer composite inorganic solid electrolyte. The battery can be twisted and even cut with scissors without causing safety problems.

However, CATL does not disclose further technical parameters such as the number of twists, and there is no plan for mass production or short-term delivery of samples.

Samsung and LG

In 2015, Samsung showed a flexible battery with a thickness of only 0.3mm, which can be twisted 50,000 times. Although the energy density of this battery is not high, using it as a strap for a smart watch can increase watch battery life by 50%.

LG's flexible battery products are similar. They can twist and bend with a radius of 15mm, and it is estimated that it can double the lifetime of wearable devices. But unfortunately, both batteries are still in the experimental stage, and no mass production has been reported.

Japan’s Panasonic

In 2016, . There are three models (CG-062939, CG-063555, and CG-064065), all of them with 3.8V (maximum charging voltage 4.35V) and capacities of 17.5mAh, 40mAh, and 60mAh. The maximum charging current is 17.5mA, 40mA, and 60mA. The thickness is only 0.55mm.

They support twists and bends and can accept up to R25mm undulations (that is, radians to a radius of 25mm arc) and ± 25 ° / 100mm changes. After repeated twists and bends, the batteries still have reliable charging and discharging characteristics. According to Panasonic, these flexible batteries still have 99% of the capacity after undergoing 1,000 twists and bend of R25mm in the test.

It can be said that these batteries have reached the commercial level. However, the capacity of the first batch of the battery is small, so it is limited to some smart bracelets without screens; it would not be able to be utilized in smart watches.

Taiwan, China’s Prologium Technology

The thickness of the ultra-thin flexible battery independently developed by Taiwan, China Prologium Technology Co., Ltd. is only 0.33mm, which can be cut like paper. Punctures, tears, impact, and even gunshots will not cause leakage. Unlike ordinary LiPo batteries, this solid-state battery can also withstand high temperatures, and it will not catch on fire or explode if it is burned by a high-temperature spray gun at 1300 degrees Celsius. A standard 182 x 230 x 0.4 mm standard flexible battery has a capacity of 1000-1400mAh.

Prologium Technology's products use printing skills and FPC flexible circuit board packaging skills, but they can only print a single layer of positive and negative electrodes. If a higher capacity is required, several batteries must be connected externally in parallel. Prologium Technology can currently supply flexible batteries for some smart cards in China, but the price is steep.

Chongqing Hanyue Technology Development Co., Ltd.

The solid electrolyte flexible battery is mainly based on the skills of thin-film batteries based on nitrogen-doped lithium phosphate (LIPON) developed by the American Oak Ridge National Laboratory at the end of the last century. The entire technology uses the magnetron sputtering method in which the solid electrolyte preparation process requires plasma enhancement to reach the nitrogen doping.

The advantages of this battery are its flexibility, thinness, high energy density, and long life. However, the disadvantage is that the technology is messy, the active material per unit area is too low, and the cost is too high. Also, it can only be used in low-energy consumption fields such as microelectronics. This thin-film battery generally has a capacity not exceeding 1 mAh and a thickness of several tens of microns. The domestic solid-state battery developed by Chongqing Hanyue Technology Development Co., Ltd. uses this technology. Its founder has been doing solid-state thin-film battery development in Japan for many years, and it is said that the company has now obtained a risk investment of 160 million RMB.

Hui Neng (Tianjin) Technology

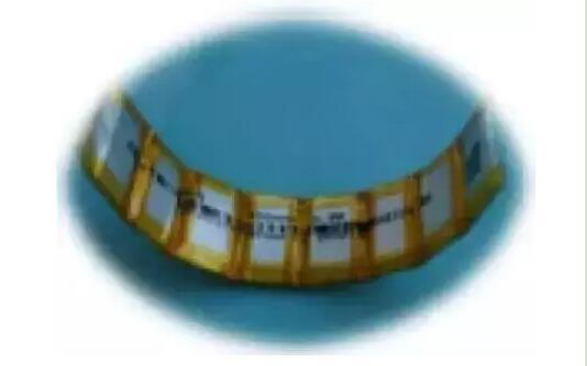

Huineng (Tianjin) Technology Co., Ltd.’s “bamboo battery” does not apply electrode material in the part of the battery that bends; this is the equivalent to connecting many small batteries in parallel. The single battery itself cannot be bent, but the whole battery string can bend. This process has high requirements on coating and packing but it works as an alternative. Tianjin Huineng has obtained angel round financing of Tianjin Teda.

Battflex

At the Shenzhen High-Tech Fair in 2016, Battflex publicly demonstrated the flexible Lithium battery they developed, as well as Bluetooth headsets and LED armbands using flexible batteries. It is understood that the flexible 3D printing technology and nanofiber-reinforced skills are used by Battflex. Their flexible battery is light, thin, and flexible and can also be used in supercapacitors and Zinc-Manganese batteries.

Nanofiber-reinforced skills help the electrode to stay intact during repeating twists without any power dropping. The capacity of the flexible battery is between 100-500mAh, the life can reach 300 cycles, the minimum tortuous arc can reach R25mm, and the number of tortuous can reach more than 1,000 times.

The company's next-generation flexible battery will use an all-inorganic solid-state system without any volatile and flammable substances.

It is reported that Battflex is also exploring the use of new packing skills to replace Aluminum-plastic film technology. The company has signed cooperative development agreements with many well-known domestic and foreign consumer electronics companies and planned to complete mass production by the end of 2017. The company also completed the first round of financing at the end of 2016.

Paper Batteries

In 2008, several battery scientists at Rensselaer Polytechnic Institute established Paper Battery Company in Troy, New York. They choose a printing process to produce super capacitors. The electrodes used are composed of high surface area activated carbon, carbon nanotubes, and graphene.

The size of this flexible supercapacitor is 7cm x 4mm x 0.3mm, and the ESR is less than 30mΩ. The company cumulatively completed more than $7 million in financing in 2015, and its products also showed up at CES 2015 and 2016 in Las Vegas, United States and gained widespread attention. This product is primarily used as a backup power source for NVDIMM memory chips, and it supplies instantaneous current pulses.

However, the process of selecting a super capacitor will limit the capacity of the product and may be difficult to use in general consumer electronics.

Zinc-manganese Flexible Batteries

Zinc-Manganese batteries , commonly known as dry batteries, are batteries primarily made with Manganese dioxide as the cathode, Zinc as the anode, and an Ammonium Chloride aqueous solution as the main electrolyte. The cathode and anode of the Zinc-Manganese battery are made of flour, starch, or the like to make the electrolyte into an inactive gel to form a separator.

The open-circuit voltage of Zinc-Manganese batteries varies with the type of MnO2 used, the composition of the electrolyte, and the pH value. Generally, it is 1.55-1.75V; the nominal voltage is 1.5V, and the most suitable application temperature is 15-30 ° C. Zinc-Manganese batteries are batteries that cannot be recharged, and its limited energy density does not allow it to be widely used in consumer electronics.

However, this flexible battery powers smart cards, music greeting cards, and electronic newspapers, as well as for RFID (radio frequency identification) electronic tags. With the rapid development of RFID skills, the potential market for this paper battery is expected to reach billions of dollars in the future.

Enfucell

Flexible zinc-manganese batteries are generally completed by screen printing. Dr. Zhang Xiachang, CTO of Finnish Enfucell Company and selected by the National Thousand Talents Plan, is the primary developer of these types of paper batteries.

In 2010, Zhang Xiachang established Ningbo Boneng Printing Electronic Technology Co., Ltd. in Ningbo National High-tech Zone to actively promote the process of professional industrialization.

The core skills of Tianjin Lvdong Power Technology Co., Ltd.'s paper batteries are derived from Israel's Power Paper. The current skills can provide a capacity density (occupying area) of about 5mAh / cm2 and a continuous current density of 0.1mA / cm2 per useful battery area. The company's products have a capacity of about 20mAh, an output voltage of 1.5V, and a square shape of 3.9 cm.

Also using similar skills and battery systems is Suzhou Changxian Optoelectronics Technology Co., Ltd.

American Blue Spark

Ohio-based Blue Spark is one of few companies to choose printing technology to make flexible batteries. The ultra-thin flexible battery developed by the company is only 625um thick. The maximum capacity is 37mAh, and the maximum output current is only 1 ~ 2mA.

The company has now received funding from Key Capital Corporation, SunBridge Partners Early Stage Partners and ORIX Capital.

Lithium-manganese Flexible Batteries

The Lithium-Manganese dioxide battery uses Manganese dioxide as the cathode active material and high specific energy metal lithium as the anode active material. The open circuit voltage is about 3.3V, the load voltage 2.8V, the nominal voltage 3.0. V, and the cut-off voltage 2.0V. The discharge voltage is relatively stable, and it is suitable for high power discharge.

Brightvolt Inc.

The American Brightvolt company claims to be able to achieve the thinnest Lithium-Manganese flexible battery with a thickness of 0.45mm and a capacity of 10mAh-48mAh.

Brightvolt claims to have selected a non-toxic, non-combustible, non-corrosive polymer electrolyte, and its negative electrode is also a printed Lithium metal paste.

And the company has sold more than one million Lithium-Manganese batteries, and its targets should be RFID, sensors, and chips.

Silver-zinc Flexible Batteries

The cathode of the Silver-Zinc battery consists of Silver oxide, and the anode of Zinc. Silver-Zinc batteries have high energy density and can discharge at high currents. Because Silver-Zinc batteries are shock-resistant, they are often used as power sources for aerospace equipment, such as spacecraft, satellites, and rockets. These batteries are used in products, such as hearing aids, electronic watches, and calculators.

The main disadvantage of Silver-Zinc batteries is that they are expensive and have a short service life. Silver-Zinc batteries can generally only be charged and discharged about 100 to 150 times. Their short lifespan is mainly due to the growth of Zinc dendrites that pierce the diaphragm.

UK’s Zinergy UK Limited

Zinergy UK Limited uses this chemistry to manufacture flexible batteries. Its founding team includes members of the Royal Academy of Engineering, Professor Gehan Amaratunga of the University of Cambridge, and Dr. Pritesh Hiralal of Cambridge University.

Zinergy has developed nano-scale electrode materials, solid electrolytes, and integrated packaging skills to develop a disposable and rechargeable ultra-thin, flexible Zinc battery. ZINERGY's formulation and mercury-free printing skills can hinder the growth of zinc dendritic crystals, thereby making zinc batteries rechargeable.

The company received an investment from Ningbo Guohua Huida Investment Company.

Imprint Energy

Another Silver-Zinc battery startup that has received much attention is from Imprint Energy from Berkely, California. In addition to screen printing to prepare the cathode, anode, and electrolytes, the company utilizes polymer electrolyte materials that prevent dendrite growth. The company also received funding from Phoenix Venture Partners and AME Cloud Ventures.

Both Imprint and Zinergy have not disclosed much detail on their battery performance, such as how many twists and turns are possible; thus, it is likely that they are still in the developmental stage of their products.

GREPOW Flexible LiPO Batteries

With its 3000+ employees and team and more than 20 years of experience in manufacturing batteries, Grepow has more than just a variety of batteries to offer its customers. We have a multitude of custom shapes and sizes available, and flexible batteries are just one of those products.

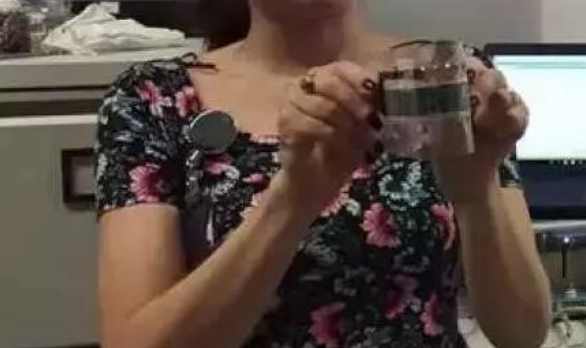

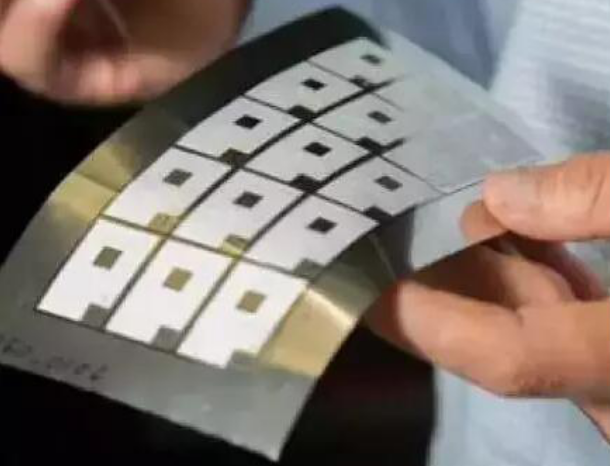

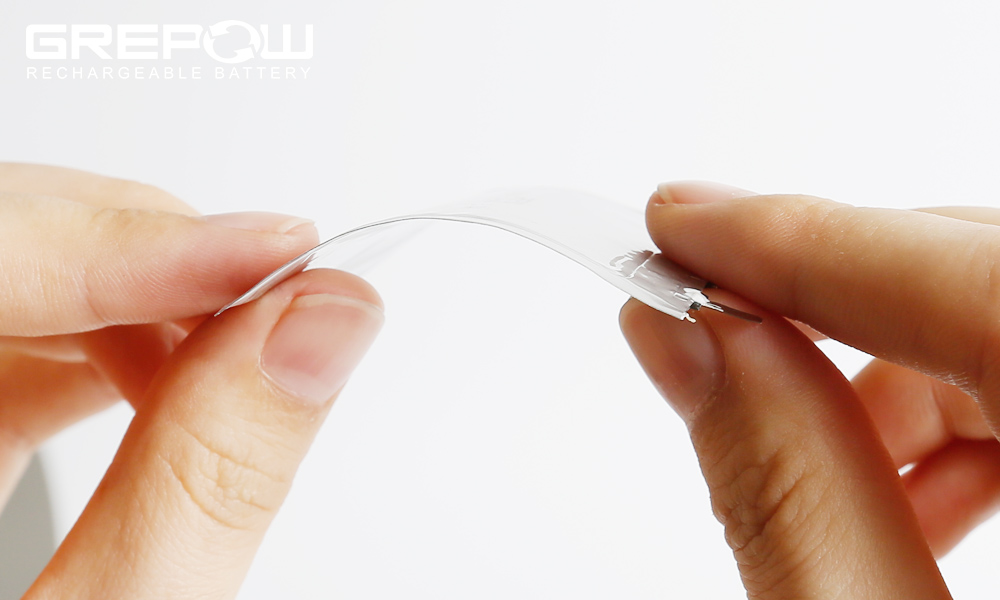

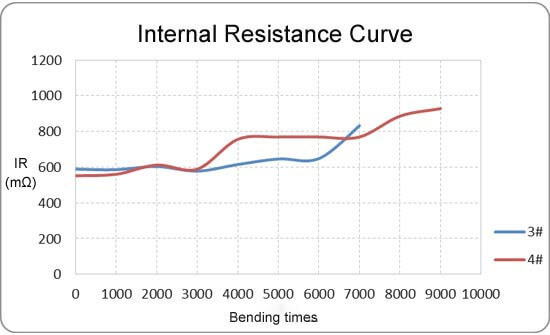

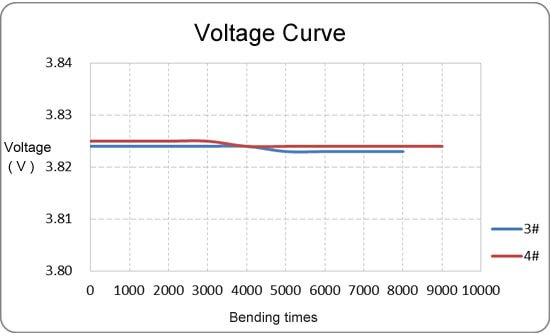

In our testing to check the bending performance of our flexible battery, we used our 0.45mm ultra-thin cells. We charged them to 3.83V and fixed them to the surface of a white PVC card. We fixed the cell pole card to our bending and torsion tester, which went 15 degrees forward and back and distorted at 30 degrees. After performing this test 9000 times, the surface of the cell was folded, and the internal pole sheet had creases. The internal resistance increased by about 45%, and the voltage before and after the bending and torsion basically remained unchanged.

Below are visuals of our testing:

If you’re interested in our flexible and custom-made batteries, please send us your device’s internal dimensions for further evaluation.

For more information, please email us: Info@grepow.com

More information on flexible shaped batteries:https://www.grepow.com/shaped-battery.html

Articles related to flexible batteries:

Flexible Batteries will Change the Future of Smart Devices

A Flexible Battery With a Thickness of Less Than 1 mm has been Developed in Japan

Flexible Paper Battery Offers Future Power

Highly Flexible High-energy Textile Lithium Battery for Wearable Electronics

Related Articles

-

What Is a Long Endurance Drone?

2025-04-16 -

Empowering Drone Training with Grepow’s Tailored Battery Solutions

2025-04-15 -

Four Specialized Lithium-Ion Battery Types Basis

2025-04-10