Grepow Semi-Solid Batteries: Four Energy Density Levels and Flexible Customization

Grepow Semi-Solid Batteries: Four Energy Density Levels and Flexible Customization

Introduction: Redefining the Power Boundaries of Industrial Drones

As industrial drones increasingly operate in extreme environments, traditional lithium batteries struggle to meet the demands for high energy density, wide-temperature operation, and rapid recharging. Leveraging 27 years of battery R&D expertise, Grepow introduces a comprehensive range of semi-solid-state batteries with energy densities of 280, 300, 330, and 350Wh/kg. With a modular series architecture and deep customization capabilities, these batteries provide all-encompassing power solutions for high-intensity applications such as delivery and power line inspections.

Key Product Highlights

Comprehensive Energy Gradient Coverage for Precise Application Matching

Model Series | Energy Density | Core Application Scenarios |

TARBG28 | 280Wh/kg | Cost-effective solution for lightweight inspection and short-haul delivery drones |

TARBG30 | 300Wh/kg | Balanced performance, suitable for power inspection equipment and medium-sized drones |

TARBG33 | 330Wh/kg | Enhanced low-temperature performance, designed for extreme cold research and power inspection robots |

TARBG35 | 350Wh/kg | Aerospace-grade lightweight battery for heavy-lift logistics and vertical take-off and landing (VTOL) drones |

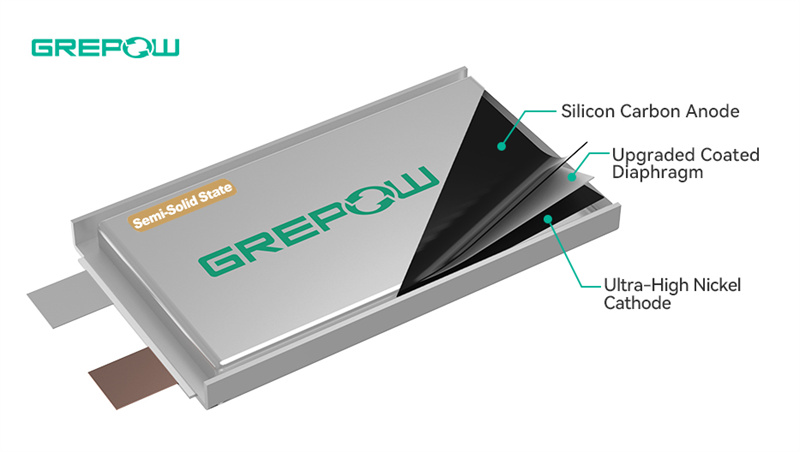

Breakthrough Technological Architecture

Dual Electrolyte Technology

Solid Electrolyte Coating: Advanced processing ensures stable ion transport and supports high discharge rates.

In-Situ Cured Gel Electrolyte: Significantly reduces the risks associated with liquid electrolytes and enhances thermal runaway resistance.

Overall Optimization: Minimizes electrolyte usage, improves energy density, suppresses dendrite growth, and extends cycle life.

High-Nickel Cathode Material

Utilizes high-nickel cathode material to enhance energy output and cycle performance, delivering superior power support for industrial applications.

Silicon-Carbon Anode Technology

Incorporates silicon-carbon composite materials to optimize lithium storage capacity, ensuring stable operation under high current density while meeting long-lifespan requirements.

Coated Separator Technology

Innovative functional coating reduces internal resistance, improves charge/discharge efficiency, and enhances safety, ensuring stable operation in complex environments.

Industrial-Grade Reliability Verification

●Extreme Temperature Adaptability: Maintains stable capacity and performance under harsh temperatures ranging from -40°C to 60°C.

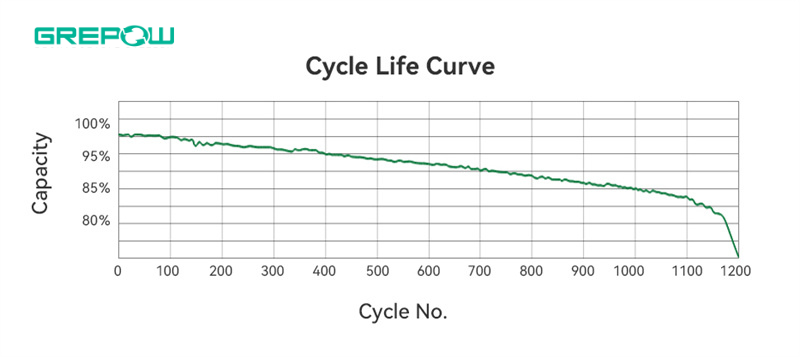

●Long Cycle Life: Rigorously tested to sustain high-performance operation under high-rate fast charging.

●Certifications and Safety Design: Compliant with international standards such as UL1642 and RoHS, with optional IP67 protection for enhanced safety assurance.

Comprehensive Customization Services

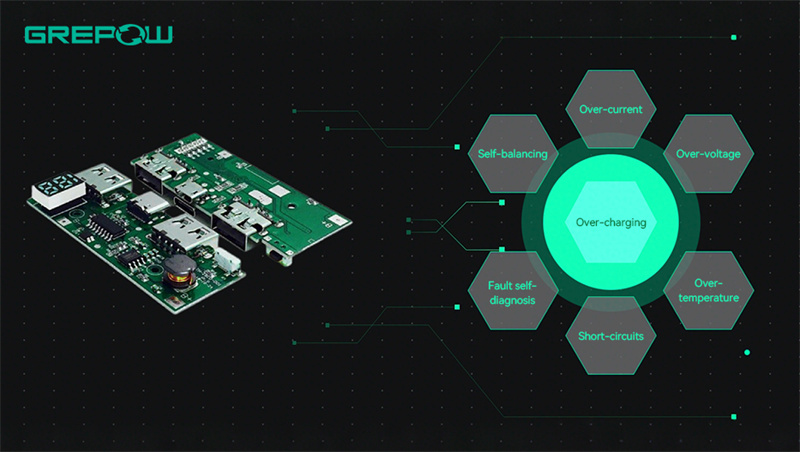

Intelligent BMS Configuration

●Supports battery state estimation based on voltage, current, internal resistance, temperature, and Kalman filtering algorithm, achieving high SOC calculation accuracy.

●Features an adaptive temperature control charging algorithm, capable of low-temperature heating and dynamic charge current adjustments for efficient and safe charging.

●Offers CANBUS/RS485 communication protocol compatibility and optional Bluetooth App integration for real-time battery status monitoring and historical log tracking.

Modular Series Architecture

●Supports up to 24S series configuration (maximum 100.8V system voltage), meeting high-power industrial drone requirements.

●Provides integrated PACK design with structural and thermal management, significantly improving space utilization and system efficiency.

Intelligent Fast-Charging Ecosystem

●Develops 5C intelligent chargers equipped with active balancing technology for ultra-fast 30-minute recharging.

●Supports multiple interface compatibility (AS150/Prolanv, etc.), ensuring seamless integration with mainstream drone platforms.

Grepow’s Manufacturing Excellence

R&D and Innovation

Employs over 300 engineers specializing in electrochemistry, materials, and structural design, continuously advancing high-performance power solutions.

High-Automation Production Lines

Utilizes upgraded manufacturing equipment to achieve intelligent, high-automation production of semi-solid-state batteries, ensuring high yield rates.

Advanced Testing Laboratories

Equipped with full-temperature environmental chambers and high-precision pulse testers to guarantee industrial-grade quality for every battery.

Production Capacity Assurance

Maintains stable monthly production capacity to meet large-scale demands, reducing lead times and enabling customers to seize market opportunities.

Conclusion: Engineered for Industrial Power

With its dual-strategy approach of "gradient product offerings + deep customization," Grepow is redefining power standards for industrial drones and high-intensity applications. Whether for extreme cold inspections or heavy-duty transport, we provide the optimal power solution tailored to your needs. Contact a Grepow engineer today to begin your customized power journey!

Frequently Asked Questions (Q&A)

Q1. What is the current development stage of Grepow’s semi-solid-state batteries?

A1. Our semi-solid-state batteries are in full-scale production, having passed multiple industrial-grade tests and certifications, earning widespread customer approval.

Q2. How can I place an order and access customization services?

A2. The

order process is streamlined and efficient:

Consultation: Contact a Grepow engineer to discuss your application requirements.

Solution Evaluation: We provide expert battery solutions, including cell selection, module design, and BMS configuration.

Sample Testing: Request samples for real-world device testing to ensure optimal compatibility.

Mass Production & Delivery: Upon solution confirmation, production commences immediately.

Q3. How does the product maintain performance in extreme environments?

A3.

Our cutting-edge technologies, including dual electrolyte and coated separator

innovations, ensure stable capacity and performance in temperatures ranging from

-40°C to 60°C, supporting high-rate discharge and fast charging.

Q4. How does Grepow ensure batch consistency in production?

A4. Our fully

automated production lines and rigorous quality control systems ensure that

every batch undergoes comprehensive testing to maintain performance

consistency.

Q5. What is the minimum order quantity (MOQ)?

A5. There is no MOQ

threshold. We support small-batch orders and offer sample testing to help

customers thoroughly evaluate product performance.

Q6. Does Grepow support non-profit research projects?

A6. Yes, we actively

support non-profit research initiatives in academic and scientific institutions.

Please contact us at info@grepow.com for tailored solutions.

Related Articles

-

What Battery Is Used In Humanoid Robots?

2024-08-30 -

Next-Generation eVTOL Battery Technology

2024-08-22 -

eVTOL Battery vs EV Battery: What’s the Difference?

2024-08-21