What Is a Drone Battery Management System and How Does It Work?

Drones have revolutionized various industries, from aerial photography and videography to delivery services and infrastructure inspection. At the heart of every drone's operation lies its battery, the source of its power and flight endurance. A Battery Management System (BMS) is a crucial component in modern drone batteries, ensuring safety, efficiency, and longevity. It acts as the "brain" behind the battery, managing and monitoring each cell within the battery pack. This article delves into the intricacies of drone BMS, exploring its functions, benefits, and the evolving landscape of this crucial technology.

What is a drone battery management system (BMS), and how does it work?

A drone battery management system (BMS) is a specialized electronic system designed to manage and protect the lithium-based battery packs used in unmanned aerial vehicles (UAVs). It builds upon the core functionalities of a general BMS, with added features and considerations tailored to the demanding requirements of drone applications.

Key Components and Workflow

●Sensors: Measure voltage, current, and temperature of each cell.

●Microcontroller: Analyzes data and triggers actions (e.g., disconnecting the load during overdischarge).

●Switching Components (MOSFETs or Relays): These components are used to control the flow of current for charging, discharging, and protection functions.

●Balancing Circuits: Redistribute energy between cells (passive or active methods).

●Communication Module: Relays data to the drone’s flight controller via protocols like CAN bus or Bluetooth.

What are the main functions of BMS for drone batteries?

Lithium-ion and Lithium Polymer (LiPo) batteries, commonly used in drones, offer high energy density but are also sensitive and require careful management. A BMS acts as the "brain" of the battery, overseeing its operation and protecting it from damage. Its primary responsibilities include:

●Voltage/Current Monitoring: Tracks individual cell voltages and overall current to prevent overcharging or over-discharging.

●Cell Balancing: Ensures uniform charge across cells to avoid capacity degradation.

●Thermal Management: Monitors temperature to prevent overheating or freezing.

●State of Charge (SOC) Estimation: Predicts remaining battery life.

●Protection Circuits: Safeguards against short circuits, overcurrent, and other faults.

●Fault Detection: Identifies issues like loose connections or internal shorts

What are the key differences between smart BMS and traditional BMS for drone batteries?

Smart BMS excels in high-performance drones by enabling real-time optimization and predictive maintenance. The evolution of BMS technology has led to the development of "smart" BMS, offering significant advantages over traditional BMS:

| Feature | Traditional BMS | Smart BMS |

| Balancing Method | Passive (resistors) | Active (energy transfer) |

| Data Analytics | Basic monitoring | Predictive algorithms, AI/ML |

| Communication Interface | Limited | Advanced (CAN, UART, Bluetooth) |

| Adaptability | Fixed parameters | Self-learning adjustments |

| Customizable Settings | No | Yes |

Why don't many drones use batteries with a BMS today?

Many drones, particularly consumer-grade and racing drones, use raw LiPo packs without a BMS. This is primarily because:

●BMS adds weight, reducing flight efficiency.

●Most hobbyist and commercial drone pilots prefer external chargers with manual balancing features.

●Some drone applications prioritize power density over safety and monitoring features.

However, as drone technology advances and the demand for longer flight times and enhanced safety grows, the adoption of BMS is expected to increase across various drone categories.

Which drones require batteries with a BMS?

While not universally adopted, certain types of drones significantly benefit from and may even require batteries with a dedicated BMS:

●Industrial and Enterprise Drones: Drones deployed in critical infrastructure inspection, agriculture, and public safety often necessitate robust battery management for safety and mission success.

●Long-Endurance Drones: Drones designed for extended flight times, such as those used for surveillance or delivery, require optimized battery management to maximize their operational range.

●Heavy-Lift Drones: Cargo carriers needing stable voltage under heavy loads.

●Drones with High-Voltage Battery Packs: Battery packs with a higher number of cells in series are more susceptible to cell imbalances and require a BMS for safe and efficient operation.

Do I need to choose a battery with a BMS for my drone?

It depends on your drone’s purpose:

●For casual or racing drones, a traditional LiPo without a BMS may be sufficient.

●For professional or industrial applications, a smart BMS-equipped battery improves safety, efficiency, and longevity.

What are the best practices for integrating a BMS into drone battery packs for optimal performance?

For manufacturers and advanced users looking to build or customize drone battery packs with a BMS, several best practices should be followed:

●Cell Matching: Use cells from the same batch to minimize imbalance.

●Thermal Design: Embed temperature sensors near hot spots.

●Firmware Updates: Ensure BMS software stays current.

●Testing: Validate under real-world conditions (vibration, temperature cycles).

●Modularity: Design for easy replacement of faulty cells or BMS components.

Other good practices include use a lightweight BMS to minimize weight impact and incorporate redundancy for critical operations.

What are the latest advancements in BMS technology for high-performance drone batteries?

The field of BMS technology is constantly evolving, with several exciting advancements relevant to high-performance drone batteries:

●AI-Driven Predictive Maintenance: Uses machine learning to optimize battery usage.

●Ultra-Fast Charging: Dynamic current adjustment prevents overheating.

●High Voltage Support: Supports voltages up to 4.45V per cell.

●Wireless BMS Systems: Reduces wiring complexity and improves reliability.

●Enhanced Telemetry Features: Provides advanced real-time data for drone operators.

●Improved Thermal Management: Enhanced cooling systems for high-performance operations.

FAQ

How does a BMS improve battery lifespan and performance in drones?

A BMS improves battery lifespan by preventing overcharging, over-discharging, and overheating. It also ensures balanced cell voltages, which maximizes the battery's usable capacity and extends its lifespan.

How does a BMS manage cell balancing in lithium-ion and LiPo drone batteries?

Passive: Burns excess energy from high-voltage cells via resistors.

Active: Transfers energy between cells using capacitors or inductors.

How does temperature monitoring and management in a BMS impact drone battery efficiency?

A BMS continuously monitors cell temperatures and can take actions to prevent overheating or undercooling. By ensuring the battery operates within its optimal temperature range, the BMS helps maintain its efficiency, power output, and longevity.

How does a BMS enable real-time battery health monitoring and telemetry data for drones?

A smart BMS communicates data like voltage, current, temperature, and charge cycles to the drone or ground control, allowing better decision-making.

How Does a BMS Enable Fast Charging?

It dynamically adjusts charging currents based on cell health and temperature, enabling faster charges without degradation.

Conclusion

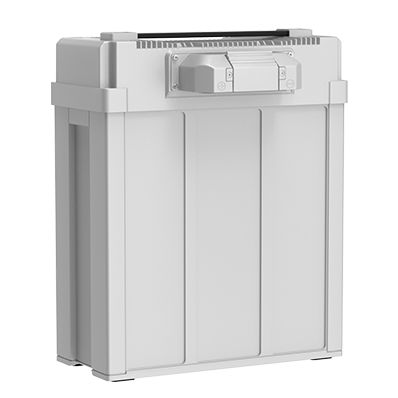

A BMS is indispensable for drones demanding reliability, safety, and peak performance. While not all drones require one, integrating a smart BMS can be a game-changer for commercial and industrial applications. As technology evolves, expect lighter, smarter systems to become the norm. Grepow has spent two decades mastering the design and production of high-performance drone batteries. The company oversees every step of battery creation—from manufacturing core cells to developing smart battery management systems (BMS) and assembling durable battery packs. This full-process control ensures top-tier quality and reliability. We offer Agricultural drone series battery, Plus series and NEO series smart Lipo batteries with advanced BMS functions for all industrial drone applications. If you have any questions or needs, please feel free to contact us at info@grepow.com.

Related Articles

-

What Is an Inspection Drone?

2025-04-21 -

What Is a Long Endurance Drone?

2025-04-16 -

Empowering Drone Training with Grepow’s Tailored Battery Solutions

2025-04-15

Related products

-

Tattu Agricultural Drone Battery

-

Tattu Plus Series Drone Battery

-

Tattu 3.0 18S Lipo 30Ah 68.4V Smart UAV Drone Battery