The top industrial battery supplier and manufacturer

Li-ion battery demand is forecast to grow about 10 fold between 2018 and 2030, mostly the industrial areas.

Unlike consumer applications, industrial batteries are defined according to different application scenarios, and are mainly used in industrial fields, such as mechanical and electrical equipment, power tools, marine equipment, base station energy storage, automotive accessories and other specific fields.

What Industrial battery factory provides?

Industrial battery is a battery designed for industrial applications. It has certain characteristics, such as high power discharge and large capacity. It is also a system that combines batteries, BMS, and chargers, which is an industrial battery.

Customized battery + BMS + Charging system

The BMS

A BMS (Battery Management System) is the intelligent component of a battery pack that is responsible for advanced monitoring and management. It plays a critical role in safety, performance, charge rates, and longevity. By monitoring the SOC (State of Charge) of the battery and managing the charge and discharge, the BMS can overall increase the efficiency and life of the battery, it is mainly used in high capacity li-ion / li-polymer / lifepo4 battery packs.

Major functions of the BMS:

Overcharge protection

Over-discharge protection

Overcurrent protection

Overheat protection

Short-circuit protection

Cell monitoring & balancing

Communication interface

Self-diagnosis

Power gauge

Customized battery

It is impossible for one battery to fit all the different industrial applications. Its voltage, capacity, and discharge current may easily meet the requirements of one device, but its size, internal resistance, temperature range, charging rate, and may not meet the requirements of another device. It is for this reason that industrial batteries must be customized. For example, if the battery has the feature of low-temperature charging, then the battery can directly be charged in the cold storage, without having to go to the saperated room and waiting for the battery to return to the normal temperature. However, it is necessary to consider the charging efficiency of the battery. At present, the charging rate of lithium batteries below 0 degrees is a negative twenty degrees 0.2C rate. It is believed that this speed will become faster and faster after the technology matures.

The industrial battery charging system

In general, the power of industrial battery chargers is relatively large; after all, the voltage and capacity of industrial batteries are relatively large, but the essentials of industrial battery chargers are to create synergistic effects with industrial batteries. Industrial batteries are biased towards customized energy solutions, so chargers need to be able to detect the state of the battery to provide the highest quality charging solution, such as determining its own charging cycle rate to adjust the charging current based on the battery's discharge state. Through the BMS, the charger can detect whether the battery has an abnormal voltage gap and remind the user that the battery needs to be replaced. Fail-safe design protects the battery when the state of charge is abnormal, but also protects the device.

Types of Battery Suppliers

Battery suppliers manufacture batteries for small electronics, transportation, and electric utility distribution and transmission grid applications. These generally fall into 2 separate categories: Lithium-Ion and Non-Lithium-Ion batteries.

Non-Li-ion Batteries

Non-Li-ion technology providers hope to capitalize on the weaknesses of Li-ion technology. Non-Li-ion battery providers include startups and large, well-established corporations. Typical non-Li-ion batteries are sodium-sulfur batteries, flow batteries, advanced lead-acid batteries, and zinc-based batteries.

Lithium-Ion (Li-ion) Batteries

Li-ion battery chemistries are proprietary to their manufacturers. Predominant chemistries are lithium cobalt oxide, which offers high energy density but can be dangerous if damaged; lithium iron phosphate; lithium-ion manganese oxide, and lithium nickel manganese cobalt oxide. Li-ion battery manufacturers are primarily based in Japan and China. They manufacture Li-ion batteries for consumer and industrial purposes. Most of these companies are partnered with car manufacturers to ensure a supply of Li-ion batteries for hybrid and electric vehicles. Factors driving Li-ion innovation are battery life, energy density, safety, cost reduction, and charging speed.

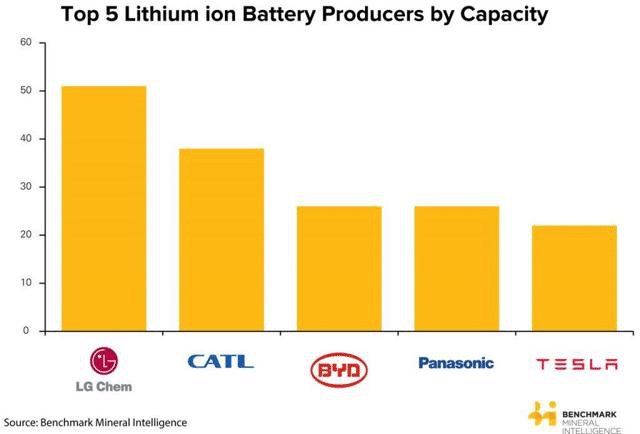

Top 5 lithium-ion manufacturers by capacity (2018)

Source: Benchmark Mineral Intelligence (published 26 January 2019)

Advantages of industrial battery system

The profitability of the manufacturing industry is constantly in a state of flux. Therefore, capacity and cost control are particularly important, and cost reduction will help factories have a greater advantage in profitability and bargaining power. Being able to achieve this goal allows these companies to maintain their profitability despite the rising and falling commodity prices. If you want to learn more about industrial batteries, please contact us.

Learn more about batteries

Keep an eye out on Grepow’s official blog, where we regularly update industry-related articles to keep you up-to-date.

Grepow website: https://www.grepow.com/

Grepow Blog: https://www.grepow.com/blog.html

Related Articles

-

High Voltage Batteries: Basics & Applications Guide

2025-02-28 -

CATL Chairman Yuqun Zeng Awarded Nobel Prize for Sustainable Development Contributions

2023-11-10 -

Resistance and Conductivity in Electric Batteries: A Simplified Explanation

2022-12-28

Related products

-

35200mAh Semi-Solid State High Energy Density Battery

-

45C High Discharge Battery - High C Rate LiPo

-

35C High Discharge Battery - High C Rate LiPo