The real cause of the mapping drone battery fire

Safety is the basis for the performance of mapping drone battery. If the battery is over-discharged, the internal chemicals break down, producing an excess of lithium oxide. Then reach the start of the fire to start burning and generate more lithium oxide, repeatedly. Chemists call it "heat out of control" and the average person sees a fire. So, what exactly caused lithium batteries to catch fire?

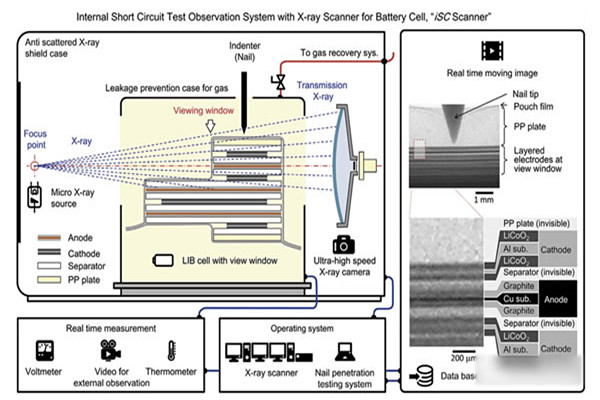

Battery acupuncture

In Japan, Tokihiko Yokoshima and others at Waseda University have done battery acupuncture test. Experimental data show that the energy of the entire battery is released in a short period of time through this short-circuit point (up to 70% of the energy is released within 60s). This can cause the temperature of the short-circuit point to rise sharply in a short period of time, which in turn can trigger a chain reaction that can cause the heat to lose control. The battery acupuncture can cause short circuits in these cells. The number of short-circuited battery cells is related to the number of battery poles that the needle passes through. When only two electrodes are shorted, not only does the battery cell short circuit. More seriously, other battery cells associated with it can also short-circuit through this short-circuit point. This means that the entire battery's charge goes through the short-circuit point, generating a lot of heat.

From the lithium battery this structural characteristics, we can easily see that the larger the battery capacity, the smaller the short circuit point will have more serious consequences. This means that the smaller the diameter of the needle used in the battery acupuncture test, the slower the acupuncture speed, the greater the risk of heat out of control. So keep away from sharp objects when using batteries. Try to use hard-packed mapping drone batteries.

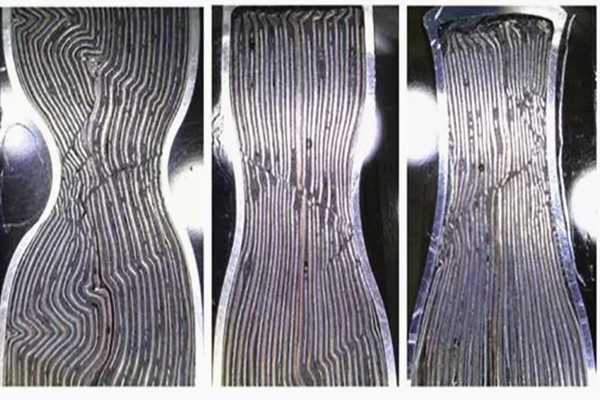

Battery drop injury

When the battery falls and hurts, it collides with a hard object. It can cause severe deformation of lithium-ion batteries, which can cause serious safety problems such as internal short circuits. Grepow technical engineers designed a rigorous extrusion test to test the safety of lithium-ion batteries in the event of a large deformation. Experiments show that during the extrusion test, the electrodes of the battery are deformed and evenly displaced at first. With the increase of deformation degree, the set fluid slips along the 45-degree slip line. Finally, the diaphragm because of the degree of deformation is too large, resulting in the diaphragm failure, causing a larger area of battery short circuit. Once an internal short circuit occurs, it can cause the lipo battery to lose control of heat, resulting in high temperatures that burn the battery. Even if there is no heat loss, local high temperatures will still melt the collecting fluid, diaphragm part. Such batteries are also no longer available. Scrap processing can only be done.

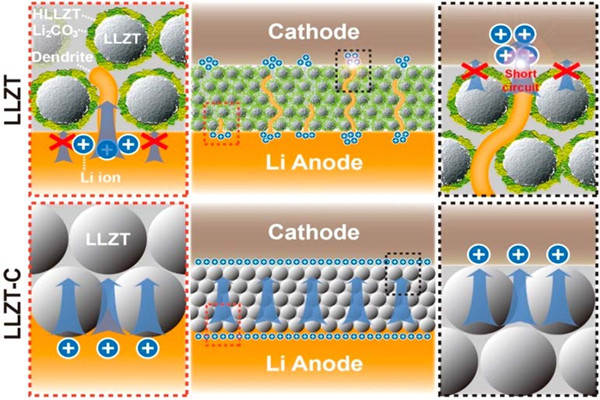

Charging too fast

The main composition of lithium polymer batteries is to use lithium alloy metal oxides as positive materials and graphite as negative materials. It uses electrolyte solutions to achieve chemical reactions and provide electricity to the battery. The principle of charging is simple, the lithium ion is at the positive pole, when discharge moved to the negative pole. The problem is that the speed at which lithium ions move is limited.Once the charging speed is exceeded, that means, there is a large current input for a short period of time. Lithium ions move too fast, or the number of lithium ions on a large scale moves over time, and the inside of the battery becomes unstable. Although many companies are actively promoting fast charging technology, charging speed is also required to meet the limits of lithium-ion. Moreover, some technologies are used to create a stable environment to prevent short-circuits. If this link is not handled properly, the short circuit will heat the electrolyte solution and the battery will catch fire.

Electrolyte material

Electrolytes are an important part of the battery, which acts as transportioning ions and conduction currents between the positive and negative poles. The electrolyte of lithium batteries must meet three requirements. First, the electrolyte has good ion conductivity. Second, the number of lithium-ion migrations of electrolytes should be as close as possible to 1:1. Third, the electrolyte needs to have sufficient mechanical strength to meet the large-scale battery production packaging process. Grepow's battery solutions use the latest folding technology. Vacuum-injected electrolytes are used in the production of batteries. Strict control of temperature and humidity. Many fire-prone batteries use poor quality electrolyte materials. Moreover, in the production process failed to achieve strict control the environment of injection of electrolyte.

Control of internal moisture

In the production of batteries, the most important link is to control moisture. Many buyers complain that the battery life they buy is short. But do not know that this and water is closely related to the factor. Battery is extremely sensitive to moisture in the workshop air, once the air moisture content in the room is too high by the battery absorption, will cause battery bloating, leakage and many other problems. Therefore, it is necessary to carry out effective environmental control of the sealing and injection process of lithium battery.

Because the normal battery lithium battery production requires moisture content below 200 ppm, so the temperature requirement in the cell room is higher than 42 degrees Celsius. If the moisture inside the battery is not well controlled, the battery temperature increases when the drone flies. Moisture can cause the battery to swell, which in turn explodes. The drone crashed and the battery caught fire. If you are interested in our medical battery, please don't hesitate to contact us at any time! Email: info@grepow.com

Grepow Website: https://www.grepow.com/

Related Articles

-

What Is a Long Endurance Drone?

2025-04-16 -

Empowering Drone Training with Grepow’s Tailored Battery Solutions

2025-04-15 -

Four Specialized Lithium-Ion Battery Types Basis

2025-04-10

Related products

-

Tattu 23000mAh 6S 22.8V 25C LiHv Pouch Cell UAV Battery

-

Tattu Plus 6S 10000mAh 22.2V 25C Lipo Smart Drone Battery

-

Tattu Pro 14S Lipo 22000mAh 51.8V Smart UAV Drone Battery Pack