Semi-Solid State Battery vs. Lithium-Ion Battery: What's the Difference?

Semi-Solid State Battery vs. Lithium-Ion Battery: What's the Difference?

The electric vehicle market is booming, expected to grow from 3 million units in 2020 to over 30 million by 2030. With this surge comes an urgent need for advanced battery technology. In this context, semi-solid-state batteries surface as a potential alternative to traditional lithium-ion batteries. This article will compare these two battery types, focusing on key performance aspects, advantages, and limitations for different applications.

What Is a Semi-Solid State Battery?

A semi-solid state battery is a type of energy storage technology that combines elements of both conventional lithium-ion and solid-state batteries. It uses a semi-solid electrolyte—usually a gel or slurry—rather than the liquid electrolyte found in traditional lithium-ion batteries or the entirely solid electrolyte in solid-state batteries, improving safety and energy density compared to traditional lithium-ion batteries.

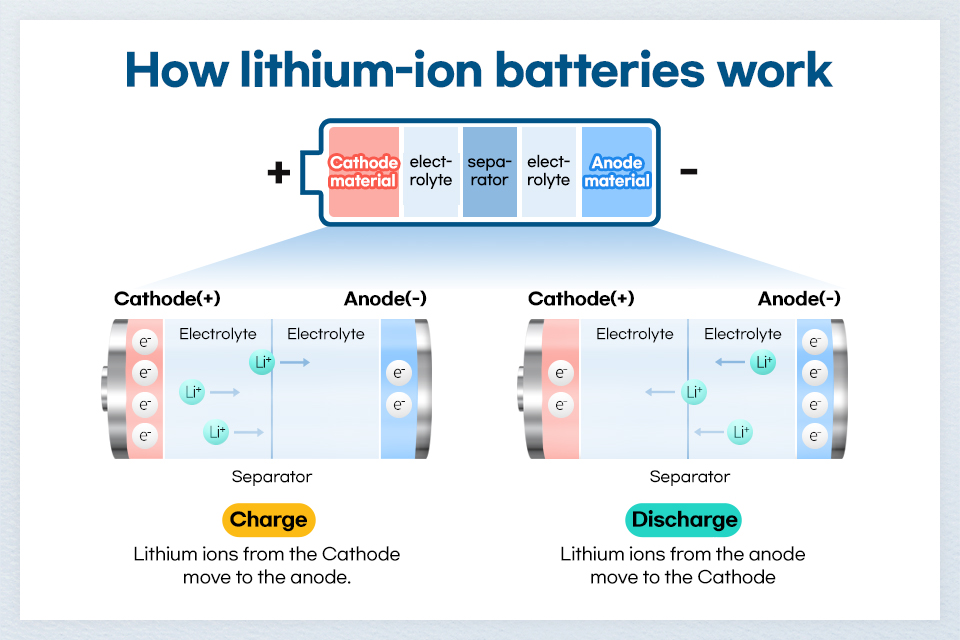

What Is a Lithium-Ion Battery?

A lithium-ion (Li-ion) battery is a widely used rechargeable battery type that stores and releases energy through the movement of lithium ions between the battery's electrodes—anode and cathode—via a liquid electrolyte. They are prevalent in various applications due to their high energy density, lightweight design, and ability to recharge quickly.

Semi-Solid State Battery vs. Lithium-Ion Battery: What's the Difference?

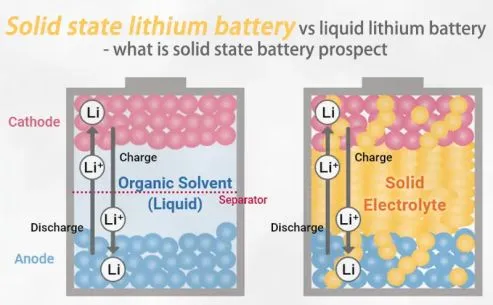

Structure

●Lithium-ion battery

Electrolytes are one of the key materials in lithium-ion batteries. The electrolyte conducts ions between the positive and negative electrode materials inside the battery. It guarantees the effectiveness of the internal circuit, plays a key role in energy density, power density, cycle life, and safety performance.

●Semi-solid state battery

The battery retains part of the electrolyte and separator structure. Semi-solid batteries need to retain a small amount of electrolyte next to the solid electrolyte to improve conductivity, so a separator is needed to separate the positive and negative electrodes. Depending on the technology, solid electrolytes also come in granular and film form.

Battery Materials

●Lithium-ion battery

The lithium-ion battery is composed of four key materials: positive electrode material, negative electrode material, separator and electrolyte, and the cost accounts for 45%, 15%, 18% and 10%, respectively. The main component of the lithium-ion electrolyte is an organic solvent, which dissolves lithium salts and provides a carrier for lithium ions.

●Semi-solid state battery

The material used is basically the same as the liquid battery. The semi-solid lithium battery uses a gel electrolyte, takes a polymer as the electrolyte “base film”, adds lithium salt, adds a low molecular organic solvent, and gets a substance with ionic conductivity between a solid electrolyte and a liquid electrolyte through immersion activation.

Energy Density

●Lithium-ion Battery

Lithium-ion batteries are the current standard in energy storage. They typically offer an energy density of around 150-250 Wh/kg and 300-700 Wh/L. Lithium-ion technology has seen improvements in energy density, but faces material-based limitations. These numbers still fall short of what’s needed for long-range electric vehicles and high-demand applications.

●Semi-solid-state Battery

Semi-solid-state batteries have the promise of much higher energy densities. Research suggests they could reach 300-500 Wh/kg and 1000 Wh/L, effectively doubling energy capacity. This represents a significant leap forward, addressing one of the prime challenges in battery technology.

Safety

●Lithium-ion Battery

Safety remains a primary concern with lithium-ion batteries. Issues like thermal runaway can lead to fires, affecting consumers and industries alike. In fact, a 2021 report indicated that over 200 incidents of battery-related fires occurred in electric vehicles globally.

●Semi-solid-state Battery

Semi-solid-state batteries feature a solid-state electrolyte. This reduces flammability and enhances thermal stability, making them inherently safer. Research shows that they have a significantly lower risk of fire or thermal runaway, adding a layer of safety appealing to manufacturers and customers.

Cycle Life

●Lithium-ion Battery

Lithium-ion batteries’ lifespan varies significantly based on material but is generally lower in durability compared to semi-solid options. Lithium-ion batteries generally have a cycle life of 500-1500 cycles depending on usage and care. Degradation over time can result in decreased capacity, often diminishing around 20% after 500 cycles in typical scenarios.

●Semi-solid-state Battery

In contrast, semi-solid-state batteries offer longer cycle life, with stability in repeated charging and discharging. Some studies indicate they could last for up to 3000 cycles, providing better longevity. This improvement comes from enhanced chemical stability in the electrolyte and fewer degradation issues.

Fast Charging

Semi-solid-state batteries support rapid charging due to more efficient ion movement, whereas lithium-ion batteries can overheat during fast charging, impacting longevity.

High and low temperature performance

Solid-state batteries have the best high temperature performance and the worst low temperature performance. Liquid batteries have the best low temperature performance and the worst high temperature performance.

Manufacturing Process

●Lithium-ion Battery

The production process of Lithium-ion batteries is divided into three stages: before, during and after. The purpose of the previous process is to process raw materials into polar sheets, and the core process is coating. The purpose of the midsection is to process the pole sheet into an inactive battery midsection process, which mainly includes the winding/stacking of the battery cell and the injection of the battery cell. The latter part of the process is testing and packaging.

●Semi-solid battery

The semi-solid battery preparation process is compatible with the traditional lithium battery production process. Semi-solid batteries can be quickly brought to market because they borrow as much as possible from existing liquid battery equipment and processes, of which only 10%-20% have different process equipment requirements.

Cost

●Lithium-ion Batteries

Lithium-ion battery prices have decreased over the past decade, averaging around $100 per kWh as of 2022. This drop has made electric vehicles more accessible, but the current technology still faces cost pressures due to raw material prices and manufacturing complexities.

●Semi-solid-state Batteries

Semi-solid-state batteries, in early production stages, are currently more costly but are expected to become more affordable as they mature . However, as technology matures, these costs are expected to fall. Reports suggest they could be closer to $100 per kWh within the next decade, appealing for large-scale production.

Applications

●Lithium-ion Batteries

Lithium-ion batteries dominate the market, widely used in consumer electronics, electric vehicles, and renewable energy storage. Their established infrastructure and reliable performance make them a go-to choice.

●Semi-solid-state Batteries

Semi-solid-state batteries hold promise for future applications where safety and energy density are crucial. They offer extended range, quicker charging, and enhanced safety, which can benefit high-stakes industries like automotive, aerospace, and grid storage.

Market Projections and Growth

Market analysts predict a robust growth trajectory for both battery types. By 2030, the semi-solid-state battery market could reach $20 billion, while the lithium-ion market may expand to $100 billion, driven by increasing demand for reliable energy storage solutions.

Conclusion

In summary, semi-solid-state and lithium-ion batteries each have distinct advantages and challenges. Lithium-ion batteries excel in current applications but present safety and lifespan issues. Meanwhile, semi-solid-state batteries could elevate performance levels, particularly in the aerospace sector. Especially designed for industrial and commercial drones, eVTOLs and other aerial/niche applications, the Grepow semi-solid state cells and packs ensure our clients can fly further, longer, and safely with record breaking Wh/L and Wh/kg energy density. If you have any questions or needs, please feel free to contact us at info@grepow.com.

Related Articles:

What Is a Semi-Solid State Battery?

Grepow Semi-Solid Batteries: Four Energy Density Levels and Flexible Customization

The Leading Semi Solid-State Battery Manufacturers of 2025

Introducing the Tattu Neo Series: Next-Gen Semi-Solid State Smart Batteries for Industrial Drones

Grepow High Energy Density Battery Solutions for Commercial Drone

Related Articles

-

Powering Aerial Artistry: Grepow Battery Solutions Behind Drone Light Shows

2025-10-27 -

Vatican Drone Show: Where Technology Meets Faith

2025-09-15 -

Why Do We Need Silent Drones?

2025-09-02

Related products

-

330Wh/kg Series Semi-Solid State High Energy Density Battery Pack

-

350Wh/kg Series Semi-Solid State High Energy Density Battery Pack

-

4.45V Ultra High Voltage Series Semi-Solid State Battery