Main Factors Affecting lithium batteries at low temperature

Lithium-ion batteries have the advantages of high operating voltage, high specific energy, long charge and discharge life, low self-discharge rate, and no memory effect. They are dominant in the global secondary battery market and have a wider range of applications, including portable electronic devices. Commercial markets such as industrial applications and power tools. The low temperature battery is widely used. Li-ion batteries will gradually become the protagonists in those areas where battery performance, reliability, and safety are high, such as aviation, aerospace, and special. However, the low-temperature performance of a lithium-ion battery, especially in a low-temperature environment below 30℃, is poor, which inhibits its application in special fields. In recent years, the low-temperature performance of the lithium-ion battery has been studied. This paper summarizes the influence factors of the low-temperature performance of the lithium-ion battery.

The effect of electrolyte

The electrolyte is an important part of the lithium-ion battery. The positive and negative electrodes in the battery are responsible for the transfer of ions. Generally, a non-aqueous organic solvent mixture in which a lithium salt is dissolved is used. Ethylene carbonate (EC), propylene carbonate (PC), dimethyl carbonate (DMC), diethyl carbonate (DEC), ethyl methyl carbonate (EMC), etc. are currently widely used in lithium-ion battery electrolytes. The organic solvent in. The effect of electrolyte on low-temperature performance is mainly reflected in its influence on conductivity and solid electrolyte phase interface (SEI) membrane properties.

(1) Conductivity

Conductivity is an important parameter to measure the performance of the electrolyte. It determines the internal resistance and rate characteristics of the electrode. Higher conductivity is a necessary condition for achieving the good low-temperature performance of the lithium-ion battery.

(2) SEI film

The composition of the electrolyte not only determines the ionic conductivity of the LR electrolyte but also the formation of the SEI film. The properties of the SEI film, such as pore porosity, electron, and ionic conductivity, the irreversible capacity of the battery, low-temperature performance, cycle performance, and safety performance Have an important impact.

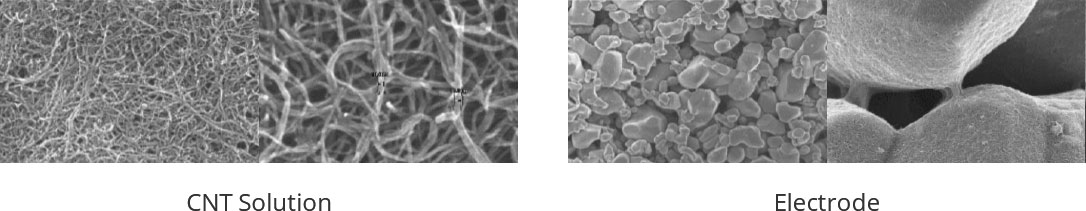

Effect of electrode material granularity

The charging and discharging process of the lithium-ion battery includes the transfer process of lithium-ions in three kinds of materials such as graphite nanoparticles, oxides, and subdivided materials, and the particle size of positive and negative materials is generally between 5 and 1.5 jam, which reduces lithium. The diffusion length of ions, but because the solid phase diffusion coefficient of lithium-ions in the electrode material is small, such as the diffusion coefficient of graphite anode material is about 10cm2 / s, the diffusion coefficient of spinel LiMnO elongated material is about 10 ClTI / s. The in-phase diffusion of lithium-ions in the electrode material towel will affect the discharge behavior of the battery. Under low-temperature conditions, the discharge of the battery is reduced, indicating that the polarization of the inner and outer layers of the positive and negative particles is increased, that is, the transmission impedance of the positive and negative solid particles of the lithium-ion is increased, resulting in the discharge cell voltage reaching the discharge termination voltage too early. The discharge capacity is also reduced accordingly.

It was found in the study that the insertion/extraction process of lithium-ions is asymmetrical under low-temperature conditions. For fully charged graphite electrodes, it is relatively easy to release the embedded lithium-ions below -20 ° C. However, at the same temperature, for the fully-released graphite, the lithium-ions are severely hindered.

The authors believe that the asymmetric process is caused by the diffusion of lithium-ions inside the graphite. By reducing the particle size of the electrode material, the low-temperature performance of the battery is significantly improved.

The effect of charge transfer resistance

The charging and discharging process of the lithium-ion battery includes the process of charge transfer of lithium-ions in the solid phase liquid phase, and also includes the charge transfer process at the electrode/electrolyte interface. The size of the resistance of the process is called charge transfer resistance. Reaction resistance. The larger the electrochemical reaction resistance, the less likely the electrochemical reaction is to proceed, or the same current is generated. The greater the electrochemical reaction resistance, the larger the overpotential required, that is, the greater the driving force required. The low-temperature performance of lithium-ion batteries was studied using anode and cathode symmetric batteries, respectively. The SEI film resistance, the interface charge transfer resistance and the diffusion coefficient inside the lithium-ion storage electrode may become the main factors affecting the low-temperature performance of the potassium ion battery in a specific system. In addition, such as electrode surface area and porosity, electrode density and thickness, binder affinity to the electrolyte, membrane porosity and wettability, etc., these factors may become the low-temperature performance of lithium-ion batteries under special circumstances. major factor.

Low-temperature battery features

This paper summarizes the research on electrolytes, electrode materials, and electrochemical reactions, and summarizes the factors affecting the low-temperature performance of lithium-ion batteries. Due to the advantages of the lithium-ion battery itself, it is extremely advantageous for the aerospace, aviation, and special fields. The tempting and low-temperature performance of Grepow low-temperature battery is greatly improved compared with the normal temperature battery, and it has been successfully applied in the aerospace field, which will greatly reduce the cost; the application in the special field can promote the development of weapons in a flexible and maneuverable direction.

Grepow low temperature shaped battery operating environment in the low-temperature range -40℃ to 50℃. The low-temperature shaped battery is a kind of special battery specially developed by Grepow, to overcome low-temperature defects inherent in the performance of chemical power supply. Grepow low temperature shaped battery adopts an innovative design concept, advanced formulation system and materials, rigorous process manufacturing process and method, and overcomes many technical bottlenecks to develop low-temperature lithium battery series. Under low temperature, the capacity of Grepow's low temperature shaped battery still over 80% by 0.2C discharge at -30 °C. This is also one of the core technologies of Grepow, which has more advantages than normal batteries.

If you are interested in our products, please don't hesitate to contact us at any time! Email: info@grepow.com Grepow Website: https://www.grepow.com/

Related Articles

-

What Is Drone Soccer?

2025-04-29 -

Practical Guide to 6S LiPo Batteries for Drones & RC Models

2025-04-23 -

What Is a BMS Battery?

2025-04-23

Related products

-

Low Temperature Shaped Battery

-

-40℃ Low Temperature LiFePO4 Battery

-

-40℃ to 60℃ Low Temperature Lipo Battery