Key Considerations for Custom Curved Batteries You Should Know

Basic properties of a custom curved battery

Battery name: curved battery | Cell Model: custom |

Battery category: lithium polymer | Battery structure: single string |

Nominal voltage: 4.35V | Battery Material: ternary |

Battery capacity: customized | Battery use: electronics |

Basic information on curved battery

What is a curved battery?

The curved battery mainly refers to the polymer curved battery, which is a kind of polymer battery. It has a curved state during the lithium battery manufacturing and molding process, and the finished product is generally seen with the arc. So most people call it a polymer curved battery.

With ultra-thin features

Another characteristic of the curved battery is that it is thinner. It is two-thirds thinner than ordinary polymer lithium batteries. The thickness can be as thin as the thickness of the card battery (Grepow ultra-thin battery can achieve 0.5mm thickness, thinner than the card)but changes in shape.

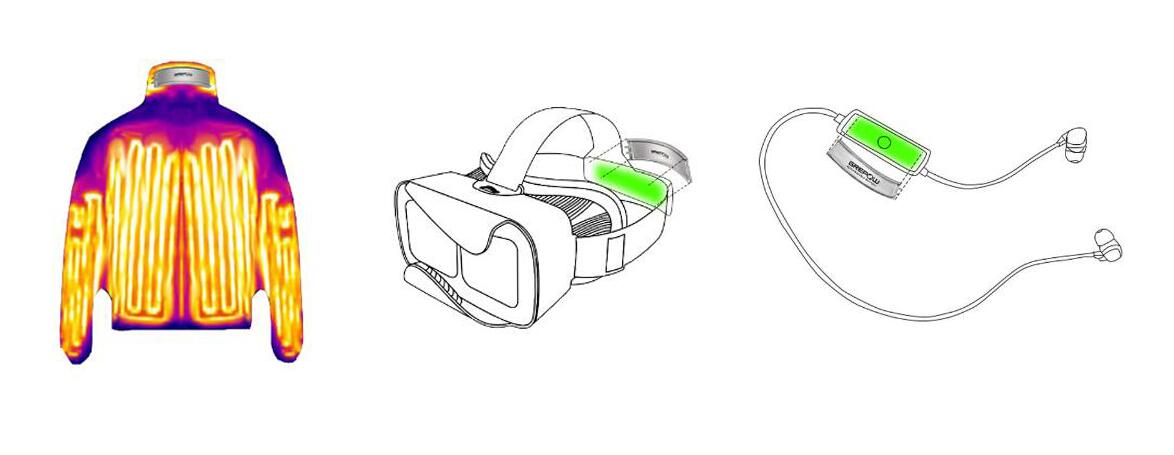

Application of curved battery

The battery capital thinks that it is the most prominent among common consumer electronics products, like smart bracelets, ultra-thin waterproof bracelets, electronic keys, Bluetooth headsets, and curved electronics. Most of the above devices are powered by this curved lithium battery.

The basic performance of the custom curved battery

Different types of curved arc batteries can be customized according to requirements.

1.Curved battery rated voltage: 4.35V.

2.Charge and discharge voltage: 3.0 ~ 4.4V.

3.Charging temperature: 0 ° C ~ + 45 ° C.

4.Discharge temperature: -20 ° C ~ + 60 ° C.

5.Storage temperature: -10 ° C ~ + 45 ° C.

6.standard charge: 0.2C, maximum charge: 2C.

7.Standard charging method: 0.2C CC (constant current) charge to 4.4V, then CV (constant voltage 4.4V) charge until charging current ≤0.05C, maximum discharge current: 2C.

8.Curved battery weight: between about 4g ~ 10g.

If the curved battery is subjected to secondary finished product PACK, then it is necessary to add protection plates, wires, insulation materials, and other methods to the battery to assemble, and 100% finished product testing, so as to ensure that the yield is improved during use. If you can contact us at info@grepow.com, we will tailor your products and ensure the safety and reliability of lithium batteries.

We can accept the customization of other parameters if you need it. Includes temperature range at temperature -50 ℃~50 ℃ or 20 ℃~80 ℃, capacity, rate, etc. Grepow can provide integrated power solutions according to customer requirements. If you need anything different from this parameter, please send us more details for the evaluation.

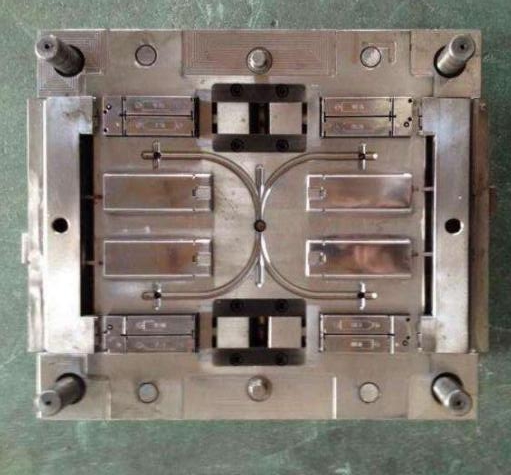

The process of a custom curved battery

Customized battery specific requirements

Because the curved battery is also called polymer curved arc lithium battery, because it is made using a polymer solution, the appearance packaging is aluminum plastic film packaging, where to make curved arc lithium batteries, please propose Your specific use of the battery, the use environment, charge and discharge specifications, finished product size requirements, voltage capacity, and other needs, our engineers will evaluate the feasibility of the solution according to your lithium battery customization needs, and then issue the corresponding technical information.

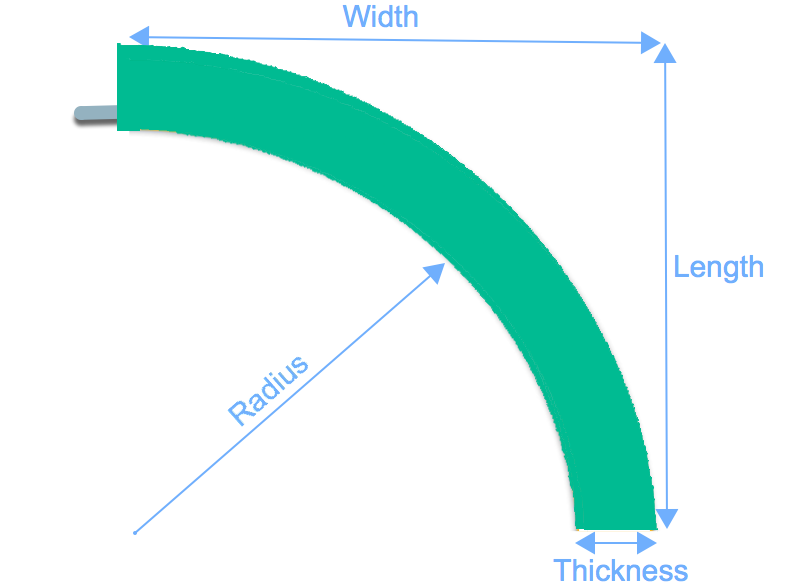

Guess how many degrees does this curved battery bend?

Guess how many degrees the polymer curved battery above is bent. Most people really can't guess exactly, suggesting that the degree of bending is less than 180 degrees.

The dimensions of the Grepow curved battery as bellow:

Thickness | Width | Inner arc length | Inner arc radius |

1.6mm-4.5mm | 6.0mm-50mm | 20mm-55mm | ≥8.5mm |

Cost of mold

We already have molds for some battery models that can be produced directly. But for the new model, the curved battery needs to be opened during the manufacturing process, which will involve the mold cost. In addition, the arc lithium battery is poor inconsistency during the production process. The yield rate is lower than that of other cylindrical 18650 lithium batteries. In terms of price, it is also higher than ordinary polymer batteries. You must be aware of this. Since portable suitcase energy storage batteries are used more outdoors, we will propose a system usage specification. Please refer to our battery use specifications for correct use. And this kind of portable suitcase energy storage battery and portable energy storage emergency power supply is in There are differences in shape and size specifications, please do not confuse.

Battery production time

The production cycle of curved arc batteries is generally 45 days after confirmation. Of course, when you contact us to make a request, we will tell you these contents. Normally, the price will be 2 hours, the plan will be delivered in 1 day, the sample will be delivered in 18 days (GREPOW provides Rapid Sampling Service, Grepow assists in cell design and cell modeling, curved arc batteries can be manufactured and tested in as early as 20 days) and the large shipment will be delivered in 50 days. Both parties confirmed the plan.

Contact us in time

If you have any other questions, please contact us in time. The above is the customized polymer curved battery for the reference of netizens. The details are subject to negotiation or contract between the two parties. Check the curved battery page for more information about the polymer curved battery.

Related Articles

-

FPV Drone Types: All You Need to Know

2025-03-06 -

The Ultimate Guide to FPV Battey

2025-02-11 -

Exploring the Power Behind Quadrupedal Robots: A Deep Dive into Robot Dog Batteries

2025-01-22