How to optimize wearable system power management?

The growth of the wearable device market is growing stronger, with sales expected to reach 600 million in the next few years, and with the rise of the Internet of Things (IoT) and the upcoming Industry 4.0, future developments are becoming more optimistic. Today, wearables are no longer just small toys, they also include many health monitoring tools used in the medical field.

The obstacle to the popularity of the wearable device market is its energy autonomy: in order to strengthen the concept of “wearable”, small batteries must be used and their energy efficiency and power management should be further improved. Highly integrated electronic devices have further improved our living environment by providing new control functions that have spawned many applications and versatile usage scenarios.

The pace of technological development is very fast, and the possibilities offered by wearable devices are already in the medical field. Wearable devices for health monitoring are able to control critical symptoms in a rigorous, real-time manner, providing medical professionals with the possibility to monitor data via cloud access. The amount of information managed by general wearable devices, visual LED interfaces, and low-power Bluetooth (BLE) communication protocols all require highly efficient power management solutions to achieve longer-life products while using energy harvesting technology to provide new charging opportunity.

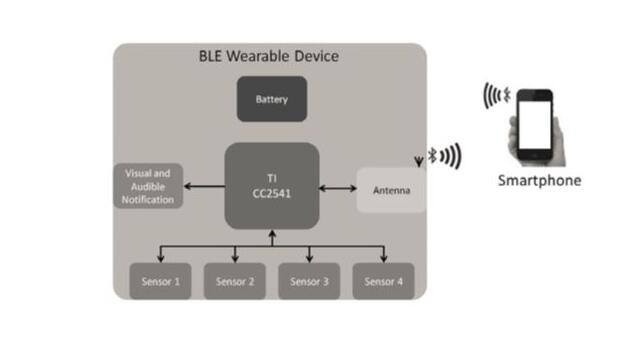

Wearable devices have proven to be fertile ground using energy harvesting technology, and one can use the kinetic energy of the wearer to generate electricity and directly charge the battery in the worn device, as shown in Figure 1.

Figure 1: wearable device built by TI CC2541 SoC.

Power mode

Designers' primary considerations are optimizing energy-saving technologies, taking advantage of low-power solutions in standby mode for a certain period of time, and waking up wearable devices such as vibrations or sudden movements with possible physical interruptions. In order to collect data, the fitness device may be in startup mode, but when motion is not detected, it may enter a power-saving state and remain in sleep or deep sleep mode as much as possible. At present, compact lithium-ion battery technology is the main energy source for wearable devices. However, the capacity is closely related to the size of the battery, and the capacity is greatly reduced after several years of use.

Customized battery solution

However, the Grepow custom battery can help you completely solve these problems. Shaped batteries not only have high energy density but also can be designed according to the shape of the equipment, making full use of the equipment space and improving the capacity. Flexible size can be customized, the special battery, the thinnest can reach 0.4mm.

Every shape is possible, such as the following: ●Ultra Thin Battery ●Curved Battery●Round Lipo Battery ●Triangle Battery ●Hexagon Battery ●Ultra Narrow Battery ●C Shape Battery ●D Shape Battery ●Polygonal Battery

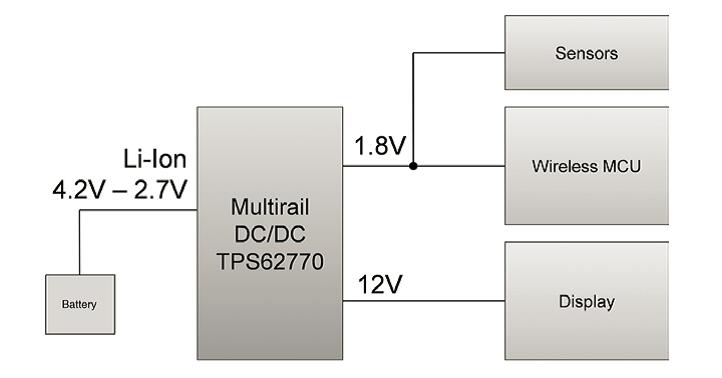

Specific energy density up to 460Wh/L lightweight, low-temperature performance, high rate of charge and discharge. Can be used normally in high temp battery 20~80℃,low temperature shaped battery -40℃~50℃ could be specially designed. One way to effectively extend battery life is to reduce the power consumption of many sensors within a wearable device. All sensors have an important role and operate at voltage levels different from the battery voltage, so they require a DC/DC converter, as shown in Figure 2.

Figure 2: multi-track dc-dc configuration

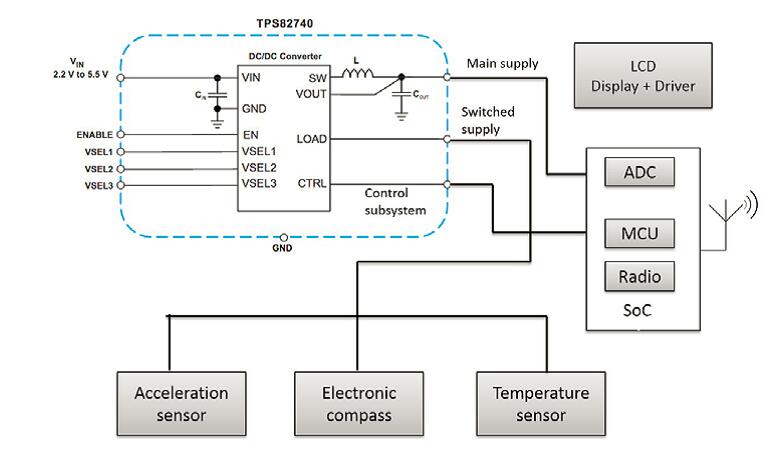

Increasing conversion efficiency directly affects battery life. The choice of the switching regulator is also one of the key factors in maximizing efficiency and determining the power level for each step of the operation. Depending on the input and output voltages, a maximum of 80% efficiency can be achieved with a low quiescent current of 1 mA. Inductor-based DC/DC switching converters are the preferred device compared to linear regulators, but adding multiple inductor-based switching regulators to meet individual voltage requirements is prohibitively expensive. Of course, you can also consider using a multi-rail DC-DC or switched-capacitor converter instead of a linear regulator to increase overall efficiency and extend battery life. A module is specifically designed to meet the power requirements of wearable devices such as smartwatches. The module uses "MicroSIP" technology (system-in-package) to integrate switched capacitors and input/output inductors in a 6.7mm2 package. The typical configuration shown in Figure 3 does not require any external components.

Figure 3: module with classical configuration

The TI module works with a direct control technique (DCSControl) that seamlessly transitions to a power-saving mode. The device can operate on rechargeable lithium-ion batteries or lithium-based batteries (than Li-SOCl2, Li-MnO2) or with two or three alkaline batteries. The input voltage is up to 5.5V, which also allows power to be taken from the USB port or thin-film solar module (if you want to use energy harvesting technology).

Thermal energy collection

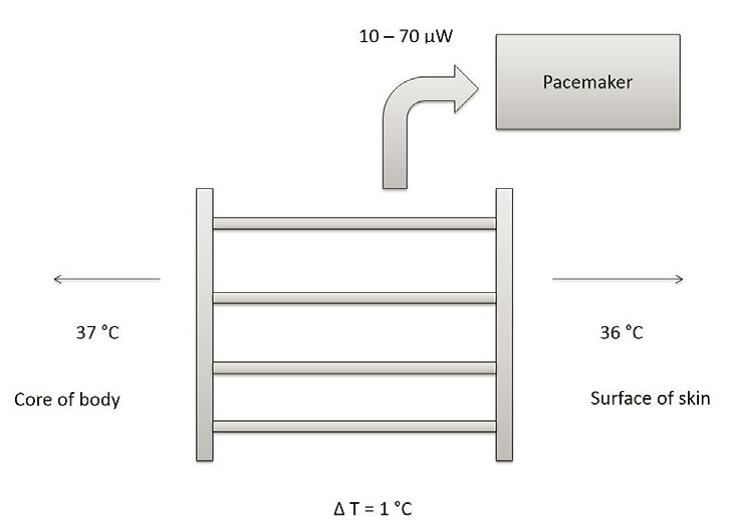

The use of a thermoelectric generator (TEG) converts thermal energy into electrical energy, the core of which is a thermopile. From the principle of thermodynamics, the thermal energy on human skin cannot be effectively converted into electrical energy, even though humans can produce more than 100W of energy on average. But we assume a low conversion efficiency of about 1% to 2%, and the energy is enough to make a low-power wearable device work. The thermal circuit generated by the TEG wearable device placed directly in contact with the skin can be described by the thermal resistance of the human body and the environment. These resistors are connected in series to represent the thermal resistance of the thermoelectric generator.

Figure 4: block diagram of pacemaker using thermal energy acquisition technology

We are always producing heat, which is a side effect of the body's metabolism. However, only a small portion of the heat is dissipated into the surrounding environment by heat and infrared radiation, and the remaining heat is suppressed in the form of water vapor. In addition, only a small portion of the heat flow can be collected and stored as energy. The magnitude of the voltage V generated between the two layers depends on the material and temperature and follows a linear relationship with the Seebeck coefficient S function.

As we have seen, energy optimization must simultaneously select the various components, as well as the power supply and the intelligent power management system that only supplies power when necessary. There are many factors to consider when designing a low-power system: power consumption, required period, voltage, and total power consumption.

Therefore, all design scenarios must be carefully planned. Email: info@grepow.com

Grepow Website: https://www.grepow.com/

US RC battery shop: https://www.genstattu.com/

EU RC battery shop: https://www.gensace.de/

Related Articles

-

How to Choose a LiPo Battery Charger?

2025-04-08 -

Join Grepow at AAA 2025+HearTECH Expo

2025-03-17 -

Join Grepow at EUHA 2024: Discover Our GRP7854 Series Hearing Aid Batteries

2024-09-25