How to Choose a LiPo Battery Charger?

When selecting a LiPo battery charger, understanding its core parameters is essential for ensuring safe, efficient, and effective charging—especially as demands grow for high-performance applications like drones, RC vehicles, and robotics. From input voltage flexibility for different power sources to output voltage compatibility with various battery configurations, each specification plays a vital role in real-world usability. This in-depth guide breaks down the critical factors—including power output, charging current, and regional AC standards—helping users make informed decisions based on their specific battery needs, charging environments, and performance expectations.

In-Depth Explanation of Core Parameters of LiPo Battery Chargers

1. Input Voltage

●Definition: The range of power supply voltage required for the charger to operate correctly (e.g., 5V USB, 12V car socket, or 100–240V AC mains).

●Impact: Determines the charger’s application scenarios (e.g., compatibility with household sockets or car use). A wide input voltage range (e.g., 12–24V) improves flexibility for outdoor use.

2. Output Voltage

●Definition: The voltage supplied by the charger to the battery, which must match the battery's number of cells in series (S count). Each LiPo cell is nominally 3.7V and fully charged at 4.2V. For example: A 6S battery requires 25.2V (6 × 4.2V).

●Impact: A voltage mismatch may prevent charging or result in overcharging (which can damage the battery). Support for a wide range of cell counts (e.g., 1–6S) improves compatibility.

3. Maximum Output Power (W)

●Definition: Output voltage × maximum charging current (e.g., 25.2V × 5A = 126W).

●Impact: If the power is insufficient, high cell count or high current charging may be limited. High-power chargers require efficient thermal design to prevent overheating.

4. Maximum Charging Current (A)

●Definition: The maximum current the charger can deliver, often expressed relative to the battery’s capacity in C-rate (e.g., for a 5000mAh battery, 1C = 5A).

●Impact: Higher current enables faster charging, but the battery must support it (e.g., a 2C-rated battery can handle 10A charging). Excessive current can cause overheating or shorten battery lifespan.

Understanding AC 110V vs AC 220V and Their Key Differences

I. Basic Definitions

AC (Alternating Current)

●Refers to electric current that periodically reverses direction and varies in magnitude. All national grids worldwide use AC.

●110V and 220V refer to nominal effective voltage values defined by local standards.

Typical Regions

●AC 110–120V: USA, Japan, Canada, Mexico, etc.

●AC 220–240V: China, most of Europe, Australia, India, etc.

II. Impact on Chargers

Compatibility Design

●Single-voltage chargers: Support either 110V or 220V only. Using with the wrong voltage (e.g., using a Japanese charger directly in China) may cause damage.

●Wide-voltage chargers: Marked 100–240V, compatible worldwide (automatically adjusted via internal circuitry).

Power Limitation

●The same charger may have reduced maximum output power when used with 110V due to input current constraints.

●Example: A charger rated for 220V/5A would need 10A at 110V for the same power. If it’s limited to 5A input, the power is halved.

Safety Risks

●Overvoltage (e.g., 110V device connected to 220V): May damage circuits.

●Undervoltage (e.g., 220V device connected to 110V): May not function or charge extremely slowly.

III. User Recommendations

Product Selection

●Choose chargers with wide input range (100–240V) for international use.

●Check the charger’s INPUT label (e.g., AC 100–240V 50/60Hz).

Plug Adapters vs Transformers

●If only plug shape differs (e.g., US vs EU), use mechanical adapters—no transformer needed.

●If voltage differs, a step-up/step-down transformer is required (though bulky and less efficient).

Safety Certification

●Prioritise products certified with UL (US), CE (Europe), or CCC (China) to ensure reliable voltage handling.

Relationship Between Maximum Output Power (W) and Maximum Charging Current (A)

When selecting a LiPo charger, prioritising maximum output power (W) vs maximum charging current (A) depends on your specific use case. However, these two parameters are tightly linked.

I. Core Relationship

●Formula: Power (W) = Voltage (V) × Current (A)

●Example: A 100W charger charging a 6S battery (25.2V) provides up to ≈4A; for a 2S battery (8.4V), it can deliver ≈12A.

●Conclusion: Power is a product of voltage and current. Usable current is limited by battery voltage.

II. When to Prioritise Power?

1. For high cell count (S) batteries (e.g., 6S drone batteries)

●High-voltage batteries (e.g., 25.2V) require high-power chargers to deliver sufficient current.

●Example: A 6S 5000mAh battery at 1C (5A) needs 25.2V × 5A = 126W. If the charger only offers 100W, current is capped at ≈4A, increasing charge time.

2. For parallel charging of multiple batteries

●Charging two 6S batteries simultaneously doubles the power requirement (252W). Sufficient power becomes a hard requirement.

III. When to Prioritise Current?

1. For low S batteries (e.g., 2S/3S RC car batteries)

●Charging current ceiling is determined by the charger’s max current output.

●Example: A 3S 8000mAh battery at 2C (16A) needs 12.6V × 16A = 201.6W. If the charger supports only 10A (despite 200W capacity), current is limited, reducing speed.

2. For fast charging large-capacity batteries

●High C-rate charging (2C, 5C, etc.) depends on current. If current is lacking, fast charging won’t work—even if power is sufficient.

IV. Buyer Decision Strategy

1. Clarify Battery Specs

●High S (e.g., 6S+): Prioritise power = battery voltage × target current.

●Low S but large capacity (e.g., 3S 10000mAh): Choose high-current (e.g., 10A+) chargers.

2. Match to Real-World Scenarios

●Power = overall cap: Must support voltage × target current of the highest S battery used.

●Current = charging speed: When power allows, higher current = faster charging for low S batteries.

3. Typical Formula

●Required power (W) = Full charge voltage per cell (4.2V) × S count × target charging current (A)

●Example: 6S battery at 5A → 4.2V × 6 × 5A = 126W

●Conclusion: Choose a charger with at least 126W power and 5A current.

Charging Time Differences Between Chargers with Varying Specs

Example: 3S 5000mAh LiPo Battery

I. Battery Specs

●Type: 3S (3 cells in series), 5000mAh (5Ah)

●Nominal Voltage: 11.1V (3×3.7V)

●Fully Charged Voltage: 12.6V (3×4.2V)

●Recommended Charging Current: 1C = 5A (standard), 2C = 10A (fast charging, if supported)

II. Comparison of Charger Parameters and Charging Time

The following three chargers represent different performance levels. The theoretical charging time is calculated using the formula: Charging Time (h) = Battery Capacity (Ah) / Charging Current (A) (ignoring the time spent on balancing):

| Charger | Maximum Power (W) | Maximum Current (A) | Theoretical Charging Time | Notes |

| A | 100W | 5A | 1 hour | Current limited to 5A. Power sufficient for standard charge. |

| B | 150W | 10A | 0.5 hours (30 minutes) | Power and current sufficient for 2C fast charge (if battery supports it). |

| C | 200W | 15A | 0.5 hours (30 minutes) | Power sufficient, but actual current limited by battery's C-rate support (2C max in this example). Offers headroom for higher S counts. |

III. Detailed Calculation Logic

1.Charger A (100W/5A)

●Power Limitation: 100W / 12.6V ≈ 7.94A (theoretical maximum current), but the charger's current limit is only 5A.

●Actual Current: 5A (limited by hardware).

●Charging Time: 5Ah / 5A = 1 hour (allow an additional 10-20 minutes for balancing).

2.Charger B (150W/10A)

●Power Verification: 10A × 12.6V = 126W ≤ 150W (sufficient power).

●Actual Current: 10A (if the battery supports 2C fast charging).

●Charging Time: 5Ah / 10A = 0.5 hours (30 minutes, requires battery to support high C-rate).

3.Charger C (200W/15A)

●Power Verification: 15A × 12.6V = 189W ≤ 200W (sufficient power).

●Actual Current: Limited by the battery. If the battery only supports 2C (10A), the current will be reduced to 10A.

●Charging Time: Same as Charger B (0.5 hours), but the remaining power can support higher S count batteries.

IV. Summary of Key Differences

1.Limitations of Charger A

●Lower current and power, only suitable for standard charging of low S count batteries and cannot meet fast charging needs.

●Example Scenario: Charging a 3S 5000mAh battery takes 1 hour. Charging a 6S battery would be power-limited (100W / 25.2V ≈ 4A, extending charging time to 1.25 hours).

2.Balance of Charger B

●Power and current match mid-range requirements, supporting fast charging (2C) for low S count batteries and 1C charging for medium S count batteries (e.g., 4S) (150W / 16.8V ≈ 9A).

●Example Scenario: Charging a 4S 6000mAh battery at 9A (approximately 1.5C) would take around 40 minutes.

3.Performance Headroom of Charger C

●High power provides reserves for parallel charging of multiple batteries or higher S count batteries (e.g., 6S), but requires battery support for high C-rates to fully utilize its potential.

● Example Scenario: Charging two 3S 5000mAh batteries in parallel (total 10Ah) at 10A each (20A total) would require 12.6V × 20A = 252W, exceeding Charger C's 200W limit. The actual current would be reduced to 200W / 12.6V ≈ 15.87A, resulting in a charging time of approximately 38 minutes.

V. User Selection Advice

1.Define Battery Requirements

●If only 3S batteries are used and fast charging is not needed, Charger A is sufficient (cost-effective).

●If fast charging is required or there's a possibility of upgrading to higher S count batteries in the future, choose Charger B or C.

2.Synergistic Consideration of Power and Current

●Formula: Charger Power ≥ Battery Full Charge Voltage × Target Current.

●Example: Charging a 6S battery (25.2V) at 5A requires 126W. If the charger's power is insufficient, the current will be forcibly reduced.

3.Safety and Expandability

●High-power chargers require active cooling and multiple protection features (e.g., ISDT Q8 Pro supports 200W/20A with a fan and temperature monitoring).

●Choose models that support multiple protocols (e.g., LiPo/LiHV) to accommodate more battery types.

The charger's power and current need to be comprehensively selected based on the battery's S number and capacity. Users with low S count batteries should focus on current, while users with high S count batteries should prioritize power. Those with multi-battery or fast charging needs should consider both. The actual charging time is also affected by the battery's chemical characteristics (e.g., maximum C-rate) and the charger's cooling capacity. It is recommended to choose models with a 20%-30% margin in parameters.

How to Choose the Right LiPo Charger?

I. Core Technologies and Features of a High-Quality LiPo Charger

Core Technologies

●Balancing Charging Technology: Ensures voltage equalisation across individual cells in a multi-cell battery, preventing overcharging/undercharging.

●Intelligent Charge Management: Automatically identifies battery type (LiPo/LiFe/NiMH) and adjusts parameters, supports fast charging standards (e.g., QC/PD).

●Multiple Protection Mechanisms: Over-voltage, over-current, short-circuit, reverse polarity protection; some include temperature sensors for overheat prevention.

●Efficient DC-DC Conversion: High conversion efficiency (>90%) reduces energy loss and heat generation.

●Cooling Design: Built-in fans/heat sinks to ensure stable operation at high power levels.

Core Features

●Multi-Function Compatibility: Supports various battery types (LiPo/LiHV/LiFe) and multiple S counts (e.g., 1-8S).

●User-Friendly Design: LCD screen for real-time display of voltage/current/capacity, preset modes (storage/discharge/balance).

●Portability and Expandability: Lightweight body, supports external power supplies (e.g., car adapter/mains).

●Safety Certifications: Complies with certifications such as CE, RoHS, UL, ensuring safe usage.

●Storage Mode: Automatically charges/discharges to 3.8V per cell to prolong battery life.

●Wireless Control: Bluetooth/App for remote monitoring of charging status.

II. User Selection Advice

●High S Count/High Capacity Battery Users: Prioritize models with high output voltage (e.g., 30V) and high power (200W+).

●Fast Charging Needs: Focus on maximum current (e.g., 10A+) and whether the battery supports high C-rates.

●Outdoor Use: Choose chargers with a wide input voltage (12-24V) and portable design.

●Safety First: Look for multiple protection features and international certifications.

By carefully matching parameters and selecting a charger with core technologies, you can significantly improve charging efficiency, safety, and battery lifespan, especially suitable for high-performance applications such as drones and RC models.

Conclusion

Choosing the right LiPo charger goes beyond just plugging in and powering up—it's about aligning technical specifications with your battery setup and usage scenarios. Whether you're working with low S count batteries and need faster charging through higher current, or handling high S count packs that demand more power, the right balance between voltage, current, and power is key. By understanding the interplay between these parameters, as well as factoring in safety features, certifications, and smart technologies, users can optimize charging performance while extending battery life and ensuring operational safety across all use cases. As a global leader in LiPo batteries for drones and RC models, Grepow offers a comprehensive range of high-quality LiPo battery charger solutions. These chargers are designed to support a wide variety of battery models and configurations, including both soft pack (pouch cell) and smart batteries. Grepow’s advanced charging systems are compatible with batteries ranging from 1S to 24S, meeting the diverse needs of hobbyists, professional drone operators, and industrial users alike. If you have any questions or needs, please feel free to contact us at info@grepow.com.

Related Articles

-

New Release | Gens ace iMars S100 G-Tech AC Balance Smart Charger

2024-07-02 -

How to Fully Charge High Voltage Lipos?

2024-06-27 -

New Release Dual Channel Smart Chargers: TA7200 and TA9000PRO

2024-05-20

Related products

-

TA9000 Plus 9000W 12-24S Dual Channel Drone Battery Smart Charger

-

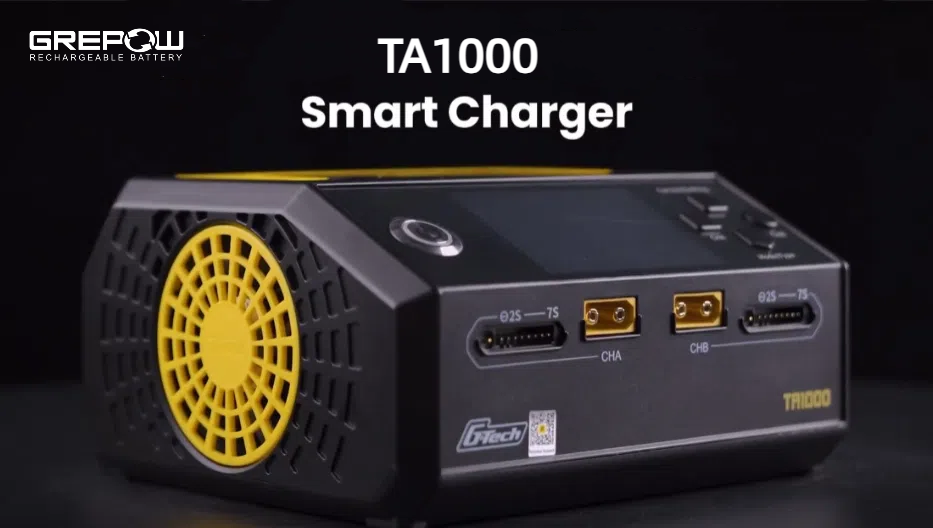

TA1000 1-7S G-Tech Smart Drone Battery Charger

-

iMars D300 LiPo Battery Charger 300W