Grepow Tattu 4.0 Smart Battery Solution for Agricultural Drones

As agricultural technology rapidly advances, drones have become essential tools for modern farming, improving efficiency, precision, and sustainability. However, one of the biggest challenges in agricultural drone operations is battery performance, affecting flight endurance, charging speed, and overall reliability. To address these challenges, Grepow has introduced the Tattu 4.0 Smart Battery Solution—an innovative, high-performance battery designed specifically for agricultural drones. With extended flight time, ultra-fast charging, and advanced safety features, the Tattu 4.0 series sets a new standard for power solutions in precision agriculture.

Development Background and Trends of Agricultural Drones

1. Development Background

●Demand for Agricultural Modernization

With global population growth and rising food demand, traditional agricultural practices face challenges such as inefficiency, high labor costs, and resource wastage. Agricultural drones, as key tools in modernizing agriculture, enable efficient and precise pesticide spraying, fertilization, and seeding, significantly improving agricultural productivity.

●Policy Support and Technological Advancements

Many countries have incorporated agricultural drones into their smart agriculture strategies, offering policy support and subsidies. For example, China's 14th Five-Year National Agricultural Mechanization Development Plan explicitly promotes drone-based crop protection. Simultaneously, rapid advancements in drone technology—such as navigation systems, sensors, and AI algorithms—have facilitated the widespread adoption of agricultural drones.

●Environmental Protection and Sustainability

Agricultural drones enable precise pesticide application, reducing chemical usage and environmental pollution, aligning with global sustainable agricultural trends. Additionally, drone operations minimize soil compaction, helping to preserve farmland ecosystems.

●Market-Driven Demand

Labor shortages and rising agricultural labor costs are driving the demand for agricultural drones. In densely populated regions such as Asia and Africa, drones are emerging as a crucial solution to address workforce shortages in farming.

2. Industry Trends

●Intelligent and Automated Operations

Future agricultural drones will be equipped with AI-driven algorithms and advanced sensors for autonomous flight planning, intelligent obstacle avoidance, and precise application of pesticides. The rise of automation will lower operational complexity and enhance efficiency.

●Multi-Functionality

Beyond pesticide spraying, agricultural drones will evolve into multi-functional farm management platforms by integrating fertilization, seeding, and pest monitoring capabilities.

●Scalability and Widespread Adoption

As drone technology matures and costs decline, agricultural drones will transition from pilot projects to large-scale commercial applications, particularly in large farms and agricultural cooperatives.

●Data-Driven Precision Agriculture

Drones will integrate with agricultural big data platforms, collecting real-time field data (such as soil moisture levels and crop growth conditions) to support precision farming, making agricultural production more scientific and data-driven.

●Advancements in Battery Technology

With improvements in battery technology, agricultural drones will utilize high-energy-density batteries for longer flight durations. Future developments may also explore hydrogen fuel cells and other alternative energy sources.

Challenges in Agricultural Drone Applications and Battery Requirements

1. Key Challenges in Drone Operations

●Limited Flight Endurance

Agricultural drones require long operational hours, but current battery technology provides only 15–30 minutes of flight time per charge. Frequent battery swaps reduce overall efficiency.

●Long Charging Time

Traditional lithium-polymer (LiPo) batteries take a long time to charge, which hinders high-intensity operations, especially during peak agricultural seasons.

●Environmental Adaptability

Field operations expose drones to harsh conditions, including high temperatures, humidity, and dust, which can degrade battery performance or cause failures.

●High Costs

Agricultural drone batteries are expensive and require regular replacement, increasing operational costs. Balancing performance and affordability remains a critical challenge.

●Safety and Reliability Concerns

Battery safety (overcharging, deep discharging, short circuits) and reliability (cycle life) directly impact drone performance and user experience.

2. Key Battery Requirements

●High Energy Density: Extends flight duration, reducing battery swap frequency and improving operational efficiency.

●Fast Charging Capability: Supports rapid charging to meet high-intensity workload demands.

●Environmental Resilience: Must withstand high temperatures, humidity, and dust to ensure stable performance in complex field environments.

●Long Cycle Life: Extends battery lifespan, reducing replacement frequency and lowering long-term costs.

●Enhanced Safety and Reliability: Prevents operational hazards and ensures consistent battery performance.

●Lightweight Design: Reduces drone weight, improving overall flight efficiency.

●Smart Battery Management System (BMS): Real-time monitoring of battery status (charge level, temperature, health) to optimize battery usage and extend service life.

Grepow Tattu 4.0 Smart Battery Solution Highlights

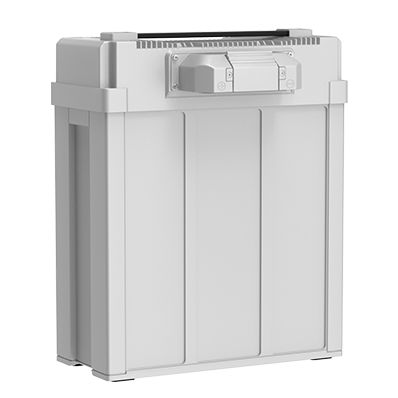

1. Extended Flight Time & Fast Charging

The Tattu 4.0 series offers high-capacity 18S 30Ah batteries, with an 18S 35Ah variant coming soon, providing extended operation time. The batteries support 4C–5C fast charging, allowing full recharge in as little as 9 minutes when used with the Tattu TA9000 Pro high-power charger. Below are the specifications of the Grepow Tattu 4.0 series smart batteries.

| No. | Battery Model | Dimension(±5mm) | Weight(±300g) | under 140A Continuous discharge(mins) | with TA9000 pro (SOC 20%-100%) | Recommended use case |

| 1 | TATTU4.0 25C 20000mAh HV 53.2V 14S1P | 103x251x261mmmm | 7900g | 7.7 mins | 9.12 mins | 20L agricultural drones |

| 2 | TATTU4.0 35C 30000mAh HV 53.2V 14S1P | 145.5x251x333.5mm | 11400g | 13.5 mins | 11.4 mins | 30L agricultural drones |

| 3 | TATTU4.0 35C 30000mAh HV 68.4V 18S1P | 324x127x274mm | 13800g | 111.5 mins | 13 mins | 50L agricultural drones |

| 4 | TATTU4.0 35C 35000mAh HV 68.4V 18S1P | Coming Soon | ||||

2. Advanced Waterproof & Humidity Resistance

A newly designed waterproof structure ensures an IP65 protection rating, effectively shielding the battery from water and pesticide exposure.

3. High-Temperature Resistance

●Heat Dissipation Window Design:

A through-channel heat dissipation structure reduces battery temperature during flight and charging. Tests show temperature drops of over 10°C during operation.

●Nine-Point Temperature Monitoring:

The battery features nine temperature sensors across the battery cells, connectors, and power circuits, enabling real-time monitoring and early alerts for potential overheating issues.

4. Wide Compatibility for Various Drone Models

●Multi-Flight Controller Compatibility:

Supports major flight control protocols, including JIYI, Boying, Mikrokopter, and DroneCAN, with adjustable communication baud rates via PC software.

●Single/Dual Battery Protocol Switching:

The built-in BMS supports single, dual, or multi-battery parallel configurations to suit different operational scenarios. When multiple batteries are connected, the system enables one-touch power-on/off while preventing reverse charging issues caused by voltage imbalances.

●Replaceable Plug Design:

The modular plug-and-play design allows users to easily replace worn-out battery connectors, reducing maintenance costs.

●Enhanced User Interface:

In addition to existing PC software and Android Bluetooth app, the new battery now supports iOS apps for battery status monitoring, firmware updates, and log exports.

5. Intelligent Monitoring & Enhanced Safety

●Improved Passive Balancing:

The upgraded BMS offers 4x faster balancing compared to previous versions, improving battery lifespan.

●Advanced Failure Detection Algorithms:

The BMS integrates multiple fault-detection mechanisms, analyzing historical usage data for early warnings of potential battery failures.

●Built-in Connection Detection:

A new position-detection mechanism prevents unintended power-on events. The battery cannot be turned on unless properly installed in the drone, reducing the risk of electrical sparks.

●Dual Safety Mechanisms:

Features MOSFET and fuse dual protection for safer battery and device operation.

●Smart Charging Management:

The new battery is exclusively compatible with Tattu chargers, ensuring optimized charging windows for intelligent battery management.

6. Durability & Extended Battery Life

●Longer Cycle Life:

When paired with a Tattu charger, the battery can achieve over 1,000 charge cycles without significant degradation.

●Slower Capacity Degradation:

Comparative tests show Tattu batteries degrade slower than competing products, retaining higher residual capacity after equal usage cycles.

7. Superior Real-World Performance

Compared to similar high-capacity drone batteries, the Tattu 4.0 series outperforms competitors in flight time, charge/discharge duration, operating temperature, thermal stability, voltage balance, BMS efficiency, and state-of-charge (SOC) accuracy. See the table below for detailed comparison data.

| Comparison Metrics | Industry Competitor | Grepow Tattu 4.0 | Comparison Results |

| Hover Time (No Load) | about 18min | about 24min | ↑ 31% |

| Hover Time(30L) | about 7.5min | about 8.5min | ↑ 13% |

| Remaining Battery Percentage After Landing (Same Test Cycles, Fully Charged, Identical Spray Volume [30L + 25L]) | 9% | 21% | 13% More Remaining Battery Capacity After Landing |

| Average Charging Time | 18.7min | 13.3min | ↓ 28% |

| Maximum Battery Temperature After Charging | 66 ℃ | 64 ℃ | ↓ 3% |

| Maximum Temperature Increase Before and After Charging | 22 ℃ | 15 ℃ | ↓ 31% |

| Maximum Battery Temperature After Landing | 68 ℃ | 61 ℃ | ↓ 10% |

| Maximum Temperature Increase After Landing | 17 ℃ | 10 ℃ | ↓ 41% |

| Battery Voltage Deviation Performance | Discharge:118mV | Discharge:23mV | |

| Charge:48mV | Charge:49mV | ||

| BMS Power Consumption | 700μA | <400μA | ↓ 42% |

| Low Battery Safe Storage Duration | 12 months | 15 months | ↑ 25% |

| State of Charge (SOC) Calculation Accuracy | 10% | <5% | ↑ 50% |

| All tests were conducted under identical equipment and parameter settings. | |||

Conclusion

The Grepow Tattu 4.0 Smart Battery Solution represents a significant leap forward in agricultural drone technology, offering longer flight times, enhanced durability, and intelligent power management. By integrating cutting-edge advancements such as fast-charging capabilities, environmental resilience, and real-time monitoring, Grepow is empowering farmers with reliable and efficient energy solutions. As agricultural drones continue to evolve, the Tattu 4.0 series ensures that operators can maximize productivity while minimizing downtime, paving the way for smarter, more sustainable farming practices. If you have any questions or needs about agricultural drone battery solutions, please feel free to contact us at info@grepow.com.

Related Articles

-

What Is a Long Endurance Drone?

2025-04-16 -

Empowering Drone Training with Grepow’s Tailored Battery Solutions

2025-04-15 -

Four Specialized Lithium-Ion Battery Types Basis

2025-04-10

Related products

-

Tattu 4.0 14S 30Ah HV 35C 53.2V Lipo Smart Drone Battery

-

Tattu 4.0 14S 20000mAh HV 25C 53.2V UAV Lipo Smart Battery

-

Tattu 3.0 18S Lipo 30Ah 68.4V Smart UAV Drone Battery