Drone battery take a place in the 5G era

With the advent of the 5G communication era, the rapid development of drone products. Behind the innovation of high-speed, high-capacity, low-latency communications technology, the demand for drone battery will also become increasing. So, in the face of the increasing demand for battery life. What are the new research advances in lithium battery technology for drones? Where will the future of battery technology revolution go?

The birth of a drone battery

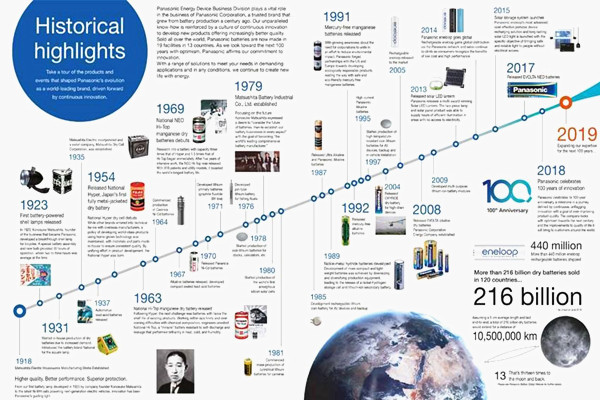

Drone battery are a derivative of the lithium battery era. Why would I say that? Follow me to learn about the history of batteries.

Modern batteries have been entering the human world for 200 years. As early as 1800, the Italian scientist Alessandro Volta invented the "voltelectric reactor". To the subsequent discovery of current, at this time the official birth of the battery is the term. When the battery voltage drops after a period of time, the battery voltage recovers. Because the battery can be recharged and can be used repeatedly, it is called a "Savings battery". Then there's the nickel cadmium battery. Until 1991, lithium batteries were introduced and commercially produced. Lithium battery with large capacity, high voltage, good cycle performance and other superior performance in the crowd of batteries, become the most ideal and most promising battery. And drone batteries are the specific application of lithium batteries in the field of drones.

The widespread use of drones in 5G

Drones are closely integrated with Internet information technologies such as big data, cloud computing, and the Internet of Things. Because industrial-grade drones will become the future with intelligent vision, deep learning of the "air intelligent robot."

In the future, 5G chips and 5G communication modules will be in place. CPE devices are no longer needed with direct built-in to 5G drones. This will greatly reduce the drone load and reduce the battery consumption. Later, charging the drone eliminates the need for manual replacement of the battery. Instead, let the drone stop directly on the charging platform for quick charging. 5G communication upgrades offer opportunities for batteries.

The current disadvantages of drone battery

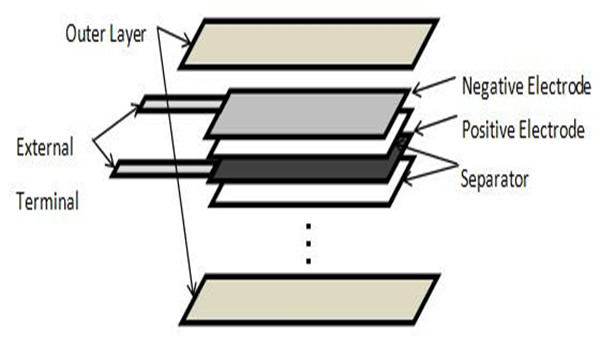

Stacked lithium cell technology mainly includes: aluminum plastic film molding, top and side seal, injection and pre-sealing, shaping and shaping, exhaust and second seal, cutting edge and folding edge.

Lithium batteries have three shortcomings, first of all, battery standardization and material cost. Since lithium batteries have a very large number of different electrical capacities and models, the degree of automation in the middle and rear sections is not as good as that of cylindrical battery production lines. This makes it impossible for batteries to be mass-produced, resulting in inefficient and costly production. The second disadvantage is the heavy reliance on imports of advanced aluminum plastic film, which increases freight costs and supply time issues. At present, the domestic batteries used in the high-end aluminum film is still dependent on imports, resulting in high cost of lithium batteries. The localization of aluminum plastic film has become one of the key factors for lithium batteries to be used on a large scale in the field of drones. The last is a fatal drawback of lithium battery technology. Because the layered battery is less automated in the production process, the consistency of the battery is poor. In the process of power battery charge and discharge, there is a problem of reduced safety and easy to produce flatgas. Lithium batteries generally bulge first in the event of a safety hazard, or crack open to release energy from the seal. The metal shell core is more prone to produce large internal pressure and explosion.

Demand and Improvement of Drone Batteries in 5G

The arrival of 5G has been a huge push to improve the technology of drone batteries. Grepow is a leader in the battery industry. At present, is also actively studying to solve the battery overheating, explosive, and has made a breakthrough. For high energy density and small capacity, it is certainly at the forefront of 5G requirements.

There are several aspects to be considered in improving the safety and the capacity of lithium batteries.

1.Small short circuit.

2.Uneven electrode (e.g. uneven density of coated surface).

3.Under a large area, how to better fit the positive and negative poles.

4.How to conduct security testing, especially for larger batteries now.

5.Reduce the characteristics of easy heat ingress of batteries, find solutions for thermal management.

Drone batteries are designed to be safe, with higher energy, good electrochemical properties, long life, small internal resistance, flexible size and shape. It's something the industry can't wait to see. The cross-border convergence between 5G and drones is actually an innovation in the digital transformation of the industry. Perhaps we can give 5G in the industrial Internet of Things and other areas, more inspiration. Only by solving these problems will there be a better battery solution in the 5G era. Tattu drone batteries also go into the sight of every flying hand in the world.

Related Articles

-

The Ultimate Guide to Grepow Jump Starter

2025-03-27 -

How to Choose Lithium Batteries for Cold Weather?

2024-09-19 -

Next-Generation eVTOL Battery Technology

2024-08-22