What's the difference between a BMS and PCM? | Battery Monday

This video would tell you about the difference between a BMS and PCM to help you determine which one is better suited for your projects.

Before we go straight into comparing these protection boards, let me help define these first.

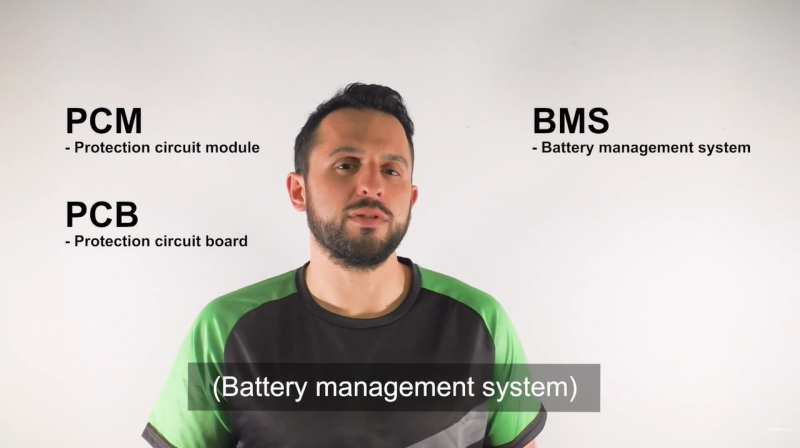

Define the PCM, PCB and BMS

Generally speaking, battery protection boards can be divided into two types. We usually refer to them as the PCM (Protection circuit module) or otherwise known as the PCB (Protection circuit board), and the BMS (Battery management system).

A battery management system (BMS) or Protection Circuit Module (PCM) is one of the most important parts of a lithium battery. Without either one of these two components, a lithium battery could be very dangerous.

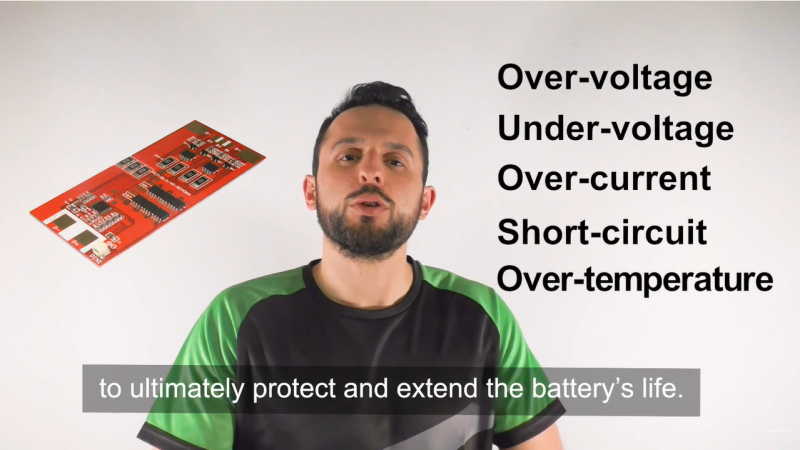

The features of PCM

The PCM is mainly composed of hardware electronic components, and it protects the charging and discharging of the lithium battery pack. When the pack is fully charged, the PCM can ensure that the voltage difference between the single cells is less than the set value in order to achieve balanced voltages between the different cells. At the same time, the PCM will detect the over-voltage, under-voltage, over-current, short-circuit, and over-temperature status of every single cell in the battery pack to ultimately protect and extend the battery's life.

The features of PCM

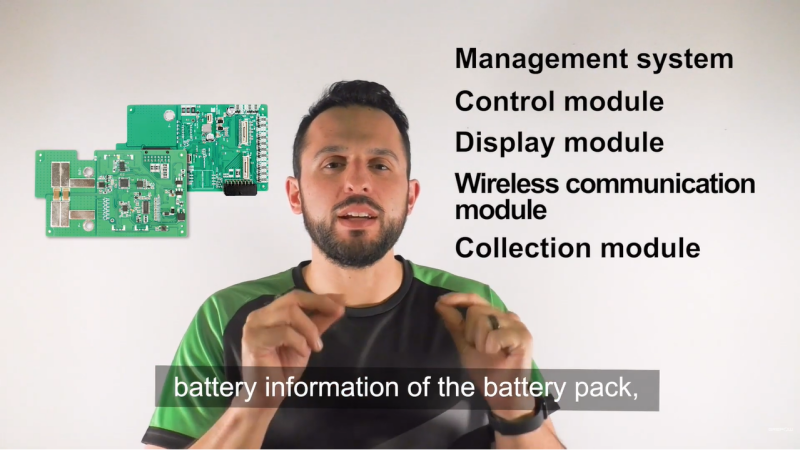

BMS modules

The BMS, also called the battery manager, maintains the same features as a PCM and PCB but also has the ability to offer additional protection and features. It provides real-time monitoring of the battery and transmits data through software. The status information is given to the electrical equipment. The BMS itself includes a management system, a control module, a display module, a wireless communication module, and a collection module for collecting battery information of the battery pack, and others.

BMS Modules

Electric shavers and power tool batteries are protected with PCM and PCB. Drones batteries, on the other hand, utilize a BMS. The drone operator will have the ability to check the battery level in real-time and calculate the remaining run time of the battery. This requires the battery to support these data transmissions, which can only be offered by a BMS.

Which solution is better for your project?

The PCM and PCB can only offer the basic levels of protection and are cheaper whereas the BMS includes all the functionalities of a PCM and PCB AND more (although the price tag increases as well). So, if you're trying to decide between these boards, it'll really depend on exactly what market your product will be geared towards. If you still can't make a decision, feel free to reach out to us, and we'll help you.

Learn More About Grepow

This is all that we're covering today. If you have any questions about today's topic or have any battery-related things you want to know, please feel free to contact us by email at info@grepow.com. We may answer your question in the next Battery Monday!

If you are interested in our high-discharge rate Ni-MH battery, please view this link: https://www.grepow.com/technology/bms.html

Please feel free to comment to let us know what could we improve and what you will to learn. We will read the comment and provide high-quality battery knowledge tutorial.

Grepow official website: https://www.grepow.com/

We would keep updating the Battery Monday every Monday!

Related Articles

-

The Ultimate Guide to Grepow Jump Starter

2025-03-27 -

How to Choose Lithium Batteries for Cold Weather?

2024-09-19 -

Next-Generation eVTOL Battery Technology

2024-08-22

Related products

-

Tattu 23000mAh 6S 22.8V 25C LiHv Pouch Cell UAV Battery

-

Tattu Plus 6S 10000mAh 22.2V 25C Lipo Smart Drone Battery

-

Tattu Pro 14S Lipo 22000mAh 51.8V Smart UAV Drone Battery Pack