An analysis of wrinkles in the coating of lithium batteries

The quality and safety of lithium batteries largely depend on the production process. In this article, we will explain the common causes and solutions for wrinkling in the coating process.

Coating

The coating process involves attaching materials with specific functions to the surface of the target substrate, replacing the solid-gas interface of the original substrate to protect the substrate or improve the surface function of the substrate, and giving the substrate new functions and characteristics. The surface characteristics of the layer improve the use value of the final product or facilitate subsequent processing. With rapid development of coated substrates in recent years, manufacturers of modern industrial products have placed higher requirements on coating technology, such as various flat surfaces, optical films for displays, flexible printed circuit boards, and new energy related lithium-ion battery electrodes. The expanding application range of precision coating has made the early textile coating be replaced with thinner and more precise film coating. The film is thinner than the textile, the substrate is thinner, and the temperature resistance is biased. However, it is easier to produce wrinkles during the coating process, which brings about bigger challenges. The coating described in this article broadly refers to the entire production line of coated products, including unwinding, coating and gluing, winding, compounding, etc. . This article will summarize the reasons and solutions for wrinkling in the coating process and provide some reference for technicians.

Causes and Solutions

Equipment and facilities

Guide roller non-parallel

No matter how high the accuracy of the equipment, after running for a period of time, the guide rollers that act on the wrap angle will shift, and wrinkles may appear due to the tension of the coated sheet. When wrinkles occur, inexperienced production teams and technicians, especially for companies that do not adopt process zero-defect control, often adjust the guide rollers at the first time and ignore other reasons that actually cause wrinkles (some parts of the guide roller are not parallel and become the most important reason for wrinkling).Solution: First, measure and observe whether the left and right diameters of the uneven single guide roller are the same. If not, replace the guide roller directly. If the left and right diameters are the same, it needs to be adjusted. Specific adjustment method: select a good reference point. First, visually measure the parallelism, observe the gap between the guide rollers, and then measure with auxiliary tools. The most practical measurement method in engineering is to use a tape measure to bypass the two guide rollers to form a closed-loop ellipse to read the circumference, and make corresponding adjustments according to the data difference.

Installing the guide roller

If the gap between two guide rollers is too small, it is easy to squeeze film into the folds before pressing. In the process of production operation, the film cannot be extended due to the bad operation of the guide roller or the dirt on the surface of the guide roller.Solution: Increase the gap between the guide rollers and reduce the wrap angle to the guide rollers in the film path. The guide roller bearing should be lubricated on time, and the surface of the guide roller should be cleaned in time to keep the guide roller clean and free of foreign objects.

Compound pressure

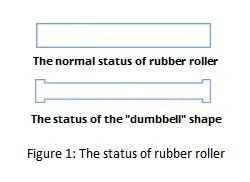

There are cases where the installation of the cylinder structure and rubber roller design is done incorrectly, which results in an inconsistent pressure on both sides of the composite roller. If the pressure of the rubber roller is set too high, it will cause the film to be pressed into a crease mark when passing through the roller surface. In the production plan, the switching between different door-width products is mainly to switch the products with narrow door-widths to products with wide door-widths especially since the products with narrow door widths have a longer production time. It is easy for the corresponding size of the narrow door width to form a certain gravure and become a "dumbbell" shape, see Figure 1. At this time, when the product is switched to a wide-width product, uneven force may appear on the gravure area and forma light indentation mark and cause severe wrinkles.

Figure 1. The status of the rubber roller

Solution: The equipment regularly performs a carbon paper test. Two sheets of A4 paper are sandwiched between the carbon paper, and the lifting rollers are placed on each end of the roller. Then the roller is pressed out, and the composite pressure on both sides is determined according to the depth of the indentation of the carbon paper. Adjustments are required. The composite pressure can be appropriately reduced in the process; the production line works best when arranging the production of products with the same width. Try to avoid producing only narrow-width products for a long period of time.

Mandatory correction

When the substrate is running, its edge position cannot be fixed at a stable position, so it is necessary to set a correction device to prevent distortion. If the position is misaligned or the correction is unreasonable, mandatory correction will occur. This phenomenon is not due to the natural shape of the coating process but due to the unwinding position and the rewinding position not being on the same line. This situation is more sensitive for production lines with shorter production line lengths. For longer production lines, due to the larger buffer space, cumulative corrections will occur during the production process and ultimately will not affect the overall production.

Solution: Turn off the unwinding or rewinding correction, let it go through a natural position to a stable position, and then open the correction, make a position identification, and serve as a fixed position for unwinding and rewinding.

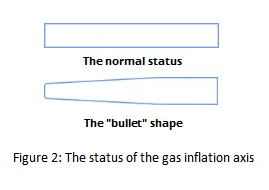

Eccentricity of gas inflation axis

Once the inflation axis occurs while there is gas and no gas, the overall curl posture will be eccentric. From the microscopic side, it changes from a rectangular to a bullet shape as shown in Figure 2. The production force is on the tight end, and the flat end is in a slack state, thus forming a situation where the force is uneven and wrinkles arise.

Solution: Replace the inflation shaft.

Figure2. The status of the gas inflation axis

Substrate problems

Uneven tension of the substrate itself

During the coating process, whether the substrate is self-produced or purchased, it is already in rolls. There will be the situations described in this article when the substrate is unrolled. There is a horizontal wide unilateral elasticity difference. The tension acts on the tight side during the production process, and the loose side becomes loose during rewinding to produce wrinkles; there is a longitudinal elasticity fluctuation, which is caused by the speed difference of the tracking roller during the production.

Solution: The substrate can be directly replaced or the unwinding tension of the substrate can be increased appropriately, but it should not be too large.

Deformation of the substrate during production

The deformation of the substrate during production is mainly affected by temperature, tension, and shrinkage when it is exposed to water. In the case of PET film, its normal softening temperature is 150℃~ 180℃. When the original film particles are mixed with impurities or the use of recycled film stretched out of the PET film, the softening temperature is less than 150℃. Production under certain process parameters will cause shrinkage and wrinkling of the film in the oven due to temperature. Hot melted adhesive film flattens under the influence of temperature and tension. After winding, the film shrinks due to thermal expansion and contraction and its own elasticity, which causes the rolled product to wrinkle especially when two different substrates are compounded. If the shrinkage of the upper and lower substrates is inconsistent, bulging or orange peel will occur. If all cotton is used and the glue applied is water-based, the cotton cloth will shrink with water. Because the width of the glue is set before shrinking, if there is no shaping equipment, the glue will shrink. At the same time, the cotton cloth will shrink during the production process under high temperatures. Therefore, when combined with other base materials and passed through a heated roller with a certain temperature, a certain deformation will occur. Under reasonable process conditions, due to the effect of tension in the coating process, this deformation does not occur significantly. After the coil is rolled, if the upper and lower substrates have insufficient bonding force or if the gluing is uneven, the bonding force will not adhere. Because this deformation is irreversible, wrinkles such as “orange peel” and bulge can appear.

Solution: Under the premise of ensuring the compound fastness and drying, reduce the temperature of the hot roller or oven to ensure that the product is normally coated with reduced or no unwinding tension. At the same time, make the winding tension as tight as possible.

Substrate tension mismatch

The wrinkles caused by this cause are mainly vertical and oblique. There are various causes of vertical wrinkles: the process tension is too large to flatten during compounding, and the upper and lower substrates are wrinkled after compounding. The causes of oblique folds include excessive tension in the process and improper rectification, resulting in unevenness of the substrate itself, uneven stress, and regular wrinkling to the loose side.Solution: The smaller the thickness of the substrate, the smaller the tension; the narrower the substrate width, the smaller the tension. If the principle is not followed, the tension does not match and wrinkling is likely to occur.

Process issues

Changes caused by tension fluctuations

The running speed of the traction roller is generally higher than the speed of the previous section. If the setting is unreasonable, wrinkling will occur. At the same time, if the substrate has longitudinal elasticity, there will be elasticity changes during the coating process due to the effect of the tension roller (tracking roller), which can cause wrinkling. Large fluctuations in the operating frequency of the motor on the equipment side will also affect the tightness changes throughout the production process, which can also cause wrinkles.

Solution: If the substrate itself is a problem, replace the substrate directly. If the tension is set too high in the process, reduce the tension appropriately. If the equipment is a problem, you need to maintain or replace the spare parts.

Heating temperature is too high

When the process has a setting for compounding the coated film, the film can become deformed and wrinkled due to excessive temperatures.

Solution: Reduce the temperature.

Thick layer

If the adhesive layer is too thick (especially when the viscosity of the adhesive is too high), the two substrates are likely to slip after composite extrusion and cause wrinkling.

Solution: Appropriately reduce the coating thickness, reduce the solid content without changing the coating thickness, or choose raw materials with a low-viscosity adhesive. In short, the appearance of wrinkles in the coating process will affect the appearance, performance and end user experience of the product. This article focuses on equipment issues such as non-parallel guide rollers, guide roller installation, compound pressure, mandatory correction, etc. Preventing wrinkling in the coating process is work that needs to be maintained frequently by Front-line technicians and production personnel. In actual production, different products or different coating methods will cause wrinkling and may even exceed the scope of wrinkling described in this article. Thus, operators must observe carefully and discover issues early, and the technical staff should analyze cases in a timely manner.

Learn more about batteries

Keep an eye out on Grepow’s official blog, where we regularly update industry-related articles to keep you up-to-date.

Grepow website: https://www.grepow.com/

Grepow Blog: https://www.grepow.com/blog.html

Related Articles

-

Practical Guide to 6S LiPo Batteries for Drones & RC Models

2025-04-23 -

How to Choose a LiPo Battery Charger?

2025-04-08 -

Join Grepow at AAA 2025+HearTECH Expo

2025-03-17

Related products

-

-30℃ 5C Low-Temperature High Discharge Battery

-

50C High Discharge Battery - High C Rate LiPo

-

45C High Discharge Battery - High C Rate LiPo

-

High C Rate LiFePO4 Battery