5 Factors That Affect the Lithium Ion Battery Life

Introduction to the structure and principle of lithium-ion battery

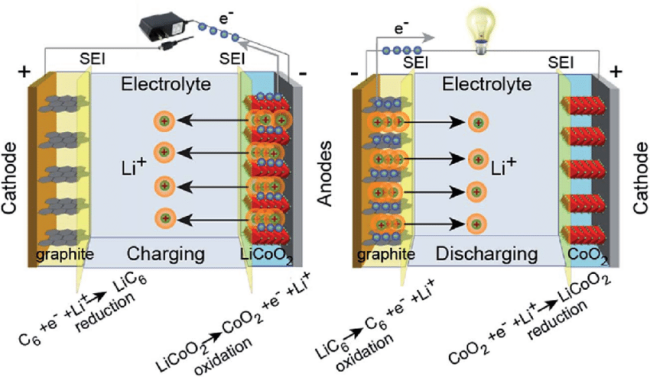

Lithium-ion battery mainly consists of positive and negative electrode materials, electrolyte, diaphragm, fluid collector and battery shell, positive and negative electrode materials consist of two different lithium-ion embedded compounds. When charging, lithium ions are embedded in the negative electrode through the electrolyte via the diaphragm, and vice versa when discharging. During the first charge and discharge of a li-ion battery, a passivation film can be formed at the phase interface between the negative electrode and the electrolyte. It acts as a diaphragm between the electrode and the electrolyte and is an electron insulator but an excellent conductor of lithium ions, which can be freely embedded and disembedded through the passivated layer and has the characteristics of a solid electrolyte. interface, or SEI film for short. The charge/discharge electrode reaction of a Li-ion battery is as follows: take LiCoO2 as an example.

Charge and discharge process of a and LiCoO2 electrodes lithium-ion cell using graphite.

The electrolyte is a very important factor

In the impact of the reversible capacity of the battery. The process of electrode material de and embedded lithium-ion is always the process of interaction with electrolyte, and this interaction has an important influence on the interface condition and internal structure change of electrode material. In the process of interaction with the positive and negative electrode materials electrolyte will be lost, in addition to the formation of SEI film and pre-charging in the battery chemistry, will also consume part of the electrolyte, so the type of electrolyte and the amount of liquid injection also affects the battery life.

The manufacturing process of a lithium-ion battery

The manufacturing process of a li-ion battery mainly includes positive and negative electrode dosing, coating, production, winding, shelling, liquid injection, sealing and formation. In the battery production process, the requirements for each step of the process are very strict. Any not well-controlled process may affect the battery cycle performance.

The process of positive and negative electrode batching

When batching positive and negative electrodes, attention should be paid to the amount of binder added, stirring speed, the concentration of slurry, temperature and humidity, and to ensure that the material can be dispersed evenly.

In the coating process

When coating, under the premise of ensuring the high specific energy of the battery, reasonably controlling the amount of positive (negative) electrode coating, and appropriately reduce the electrode thickness to help reduce the decay rate of the battery. After coating, the electrode will be further compacted by roller press. A proper positive electrode compacting density can increase the discharge capacity of the battery, reduce the internal resistance, reduce the polarization loss and extend the cycle life of the battery.

When winding

In the winding process, the rolled cell should be tight and not loose. The tighter the diaphragm and positive and negative electrodes are rolled, the smaller the internal resistance, but when rolled too tightly, it will cause difficulties in wetting the electrode and diaphragm, resulting in a smaller discharge capacity; rolled too loosely will make the electrode over-expand during charging and discharging, increasing the internal resistance, reducing the capacity and shortening the cycle life.In the battery design process, the selection of materials is the most basic and important factor. The performance characteristics of different materials are also different, and there is a gap in the performance of the battery developed. The cycle life of the battery will be long only if the positive and negative materials are matched with good cycle performance. In terms of ingredients, attention should be paid to the amount of positive and negative materials added. Generally speaking, the design assembly process generally requires the negative electrode capacity relative to the positive electrode in excess of some, if not, the negative electrode will precipitate lithium in the charging process, the formation of lithium dendrites thus affecting safety. If the negative electrode is too much relative to the positive electrode, the positive electrode may be excessively de-lithiumed, resulting in structural collapse.

The impact of aging and decline of battery materials

Lithium-ion battery charging and discharging cycle is the process of lithium ions through the electrolyte in the positive and negative electrode material back and forth between the process of de-embedding and moving. In the lithium-ion battery cycle process, in addition to the redox reaction in the positive and negative electrodes, there are also a large number of side reactions. If the side reactions of lithium-ion batteries can be reduced to a low level, so that lithium ions can always go back and forth between the positive and negative materials through the electrolyte, the cycle life of lithium-ion batteries can be increased.

The influence of the battery use environment

The use of lithium-ion battery environment in its cycle life is also very important. Among them, the ambient temperature is a very important factor. The ambient temperature is too low or too high will affect the cycle life of lithium batteries.

Low temperature

The constant voltage charging time increases at low temperatures, and the charging performance also deteriorates significantly.

High temperature

With high temperature charging and discharging, the negative electrode performance will gradually deteriorate eventually leading to battery failure.

Strong vibration or shock

Under strong vibration or shock, the pole lugs, external connecting wires, terminals, solder joints, etc. of lithium-ion batteries may break or fall off, and the active material on the battery pole pieces may also be peeled off, which will affect the life of the battery or even produce dangerous situations.

The impact of the charge and discharge system during the cycle

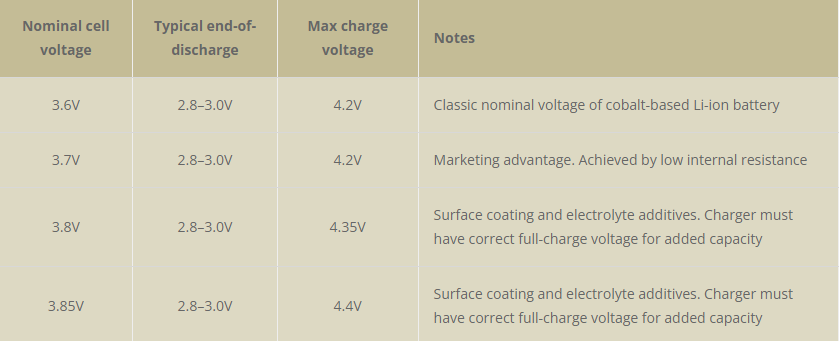

The use of lithium-ion batteries is the process of charging and discharging cycle, the size of the charge and discharge current, the choice of charge and discharge cut-off voltage and the use of what charge and discharge system on the cycle life of lithium-ion batteries also has a very important impact. Any blind increase in the working current of the battery, increase the charging cut-off voltage, lower the discharging cut-off voltage, etc. will degrade the performance of the battery. Different electrochemical systems of lithium-ion batteries have different charge and discharge cut-off voltages.

Source: Battery University

As the battery needs to discharge a large capacity in a relatively short period of time when discharging at high current, the electrode reaction is rapid and violent, and some lithium ions are too late to deembed or cross the negative electrode material discharge process is over. In addition, the battery lugs may melt under high current conditions and equipment components may be damaged.

Conclusion

Whether in design and manufacture or in use, there are multiple factors that affect the cycle life of rechargeable lithium-ion batteries.If you like the article, don't forget to follow us: Grepow Blog

Related Articles

-

How to Choose a LiPo Battery Charger?

2025-04-08 -

Join Grepow at AAA 2025+HearTECH Expo

2025-03-17 -

Join Grepow at EUHA 2024: Discover Our GRP7854 Series Hearing Aid Batteries

2024-09-25