3 Different Shapes Lithium Battery Structures

At present, there are three main types of mainstream lithium battery structures, namely, cylindrical, rectangular and pouch cells. Different lithium battery structure means different characteristics, and each has its own advantages and disadvantages.

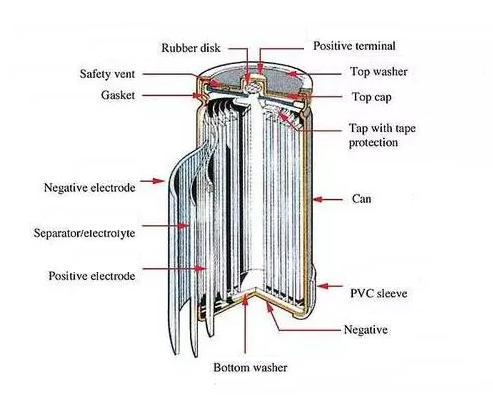

1. The cylindrical lithium battery structure

The round lithium battery refers to the cylindrical lithium battery. Because the history of the 18650 cylindrical lithium battery is quite long, the market penetration rate is very high. The cylindrical lithium battery adopts various mature replacement processes, the degree of automation is high, and the product mass transfer is stable. The cost is relatively low. Cylindrical lithium batteries are available in a variety of models, typically 14650, 17490, 18650, 21700, 26650, etc. Lithium-ion batteries are widely used in lithium batteries in Japan and South Korea. There are also large-scale enterprises in China that produce cylindrical lithium batteries.

With the further expansion of the electric vehicle market and the continuous improvement of the cruising range, the vehicle manufacturers have put forward higher requirements on the energy density, manufacturing cost, cycle life and product additional attributes of the power battery.

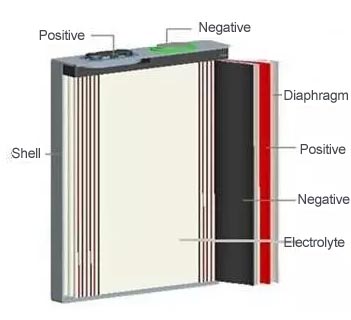

2. The rectangular lithium battery structure

Rectangular lithium battery usually refers to an aluminum shell or steel shell rectangular battery. The expansion rate of the rectangular battery is very high in China. It is the rise of automobile power battery in recent years. The difference between vehicle cruising range and battery capacity is becoming more and more obvious. The aluminum-shell rectangular battery with high battery energy density is mainly because the structure of the rectangular battery is simple, unlike the cylindrical battery, which uses high-strength stainless steel as the housing and accessories such as explosion-proof safety valves, the overall accessory weight is light. The relative energy density is higher. Rectangular batteries have two different processes, winding and lamination.

Rectangular lithium battery usually refers to an aluminum shell or steel shell rectangular battery. The expansion rate of the rectangular battery is very high in China. It is the rise of automobile power battery in recent years. The difference between vehicle cruising range and battery capacity is becoming more and more obvious. The aluminum-shell rectangular battery with high battery energy density is mainly because the structure of the rectangular battery is simple, unlike the cylindrical battery, which uses high-strength stainless steel as the housing and accessories such as explosion-proof safety valves, the overall accessory weight is light. The relative energy density is higher. Rectangular batteries have two different processes, winding and lamination.

However, since rectangular lithium batteries can be customized according to the size of the products, there are thousands of models on the market, and because of too many models, the process is difficult to unify. Rectangular batteries are no problem for use on ordinary electronic products, but for industrial equipment products that require multiple strings and parallels, it is best to use standardized production of inserted lithium batteries. This production process is guaranteed, and it is easier to find alternatives later. battery.

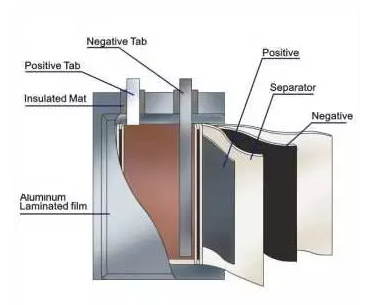

3. Pouch Cell

The key materials used in pouch cell—positive materials, anode materials, and separators—have little difference from traditional steel and aluminum-shell lithium batteries. The biggest difference is the flexible packaging material (aluminum-plastic composite film). It is the most critical and technically difficult material in the pouch cells. The flexible packaging material is usually divided into three layers, namely an outer resist layer (generally an outer protective layer composed of nylon BOPA or PET), a barrier layer (intermediate aluminum foil) and an inner layer (multifunctional high barrier layer). The packaging material and structure of the pouch cell gives it a number of advantages.

The key materials used in pouch cell—positive materials, anode materials, and separators—have little difference from traditional steel and aluminum-shell lithium batteries. The biggest difference is the flexible packaging material (aluminum-plastic composite film). It is the most critical and technically difficult material in the pouch cells. The flexible packaging material is usually divided into three layers, namely an outer resist layer (generally an outer protective layer composed of nylon BOPA or PET), a barrier layer (intermediate aluminum foil) and an inner layer (multifunctional high barrier layer). The packaging material and structure of the pouch cell gives it a number of advantages.

3.1 Safety performance

The pouch cell is packaged in aluminum plastic film. When a safety problem occurs, the pouch cell will generally be blown apart, unlike the steel shell or the aluminum shell.

3.2 Lightweight

pouch cell weight is 40% lighter than steel shell lithium battery of the same capacity, 20% lighter than aluminum shell lithium battery.

3.3 The internal resistance is small

and the internal resistance of the pouch cell is smaller than that of the lithium battery, which can greatly reduce the self-consumption of the battery.

3.4 The cycle performance is good

For the cycle life of the pouch cells longer, and the attenuation of 100 cycles is 4% to 7% less than that of the aluminum case.

3.5 Flexible design

variable shape and any shape can be thinner, such as the following:

●Ultra-Thin Battery,●Curved Battery,●Round Batteries,●Triangle Battery,●Hexagon Battery,●Ultra Narrow Battery,●C Shape Battery,●D Shape Battery,●Polygonal Battery,●Rectangle Battery

We can customize and develop novel battery models according to customer needs.

The shortcomings of the pouch cell are poor consistency, high cost, and easy liquid leakage. The high cost can be solved by large-scale production, and the leakage can be solved by improving the quality of the aluminum-plastic film.

4. Comparative analysis of technical characteristics

4.1 Battery shape

Rectangular lithium batteries can be of any size, so they are not comparable to cylindrical batteries.

4.2 Rate characteristics

Cylindrical lithium battery soldering multi-pole process limitations, so the rate characteristics are slightly worse than the rectangular multi-pole solution

4.3 Discharge platform

The same positive electrode material, negative electrode material, and electrolyte are used, so the theoretical discharge platform is consistent, but the internal resistance of the rectangular battery is slightly dominant, so the discharge platform is slightly higher.

4.4 Product quality

The process of cylindrical lithium battery is very mature, the probability of secondary slitting defect is low, and the winding process is higher than the lamination process maturity and automation. The lamination process is still in semi-manual mode, so the quality of the battery There are adverse effects.

4.5 Tab welding

Cylindrical lithium battery poles are easier to solder than rectangular lithium batteries, and rectangular batteries are prone to cause solder joints to affect battery quality.

4.6 Pack grouping

The circular battery is relatively easy to use, so the packing scheme is simple, the heat dissipation effect is good, and the rectangular battery pack should solve the problem of heat dissipation.

4.7 Structural features

the chemical activity of the rectangular battery is poor, and the performance of the battery for long-term use is more obvious.

In short, whether it is cylindrical, rectangular or pouch cell, the current rapid development is because they are well applied in their respective application areas. Domestic battery manufacturers are predicting that the rectangle will become the mainstream of the battery, but the battery application manufacturer represented by GREPOW is constantly innovating in technology, the battery energy density is continuously improved, and the battery performance is more excellent.

If you are interested in our products, please don't hesitate to contact us at any time!

Email: info@grepow.com

GREPOW Website: https://www.grepow.com/

Related Articles

-

Join Grepow at TAITRONICS & AIoT Taiwan 2024 to Discover New Innovations!

2024-10-19 -

What Batteries Are Used for AGVs and AMRs?

2024-09-30 -

How Are Smart Rings Powered?

2024-09-05